Fabric Duct Longevity and Durability

When people first hear about fabric ducts, they often have many questions about them: how do they stay inflated? Why fabric and not sheet steel? What about vibration? But the most common reservation we encounter is: how long do they last? Many people assume fabric ducts are a temporary solution, but for long term durability, they come through with flying colours. But how do they measure up against traditional ductwork?

Safe from corrosion and chemical damage

All metals can corrode depending on their environment, even stainless steel. In very humid environments, this can severely affect the longevity of the ductwork, especially if there are also condensation issues. Using a polyester-based textile material eliminates this problem: our specially developed fabric ducting material is impervious to oxidation and corrosion.

However, even fabric ducts are not entirely free of metal components as the mounting equipment, hooks, profiles and zippers are all usually metallic. Where a corrosive environment is expected, such as at swimming pools and leisure centres, we minimise risks by selecting special equipment such as corrosion resistant zippers and internal plastic rings.

Not affected by thermal cycling

Ducts carrying both hot and cold air are subjected to thermal stresses, which can shorten the lifespan of many types of duct. This issue is common with traditional metal ducting, especially those with insulation or coatings. Fabric ducts are not susceptible to this. The textile material that makes up the fabric ducts is woven and flexible, adapting perfectly to temperature changes.

Immune to damage from accidental impact

Dents and bumps in ductwork are not just unsightly – they can affect the ventilation system’s performance. Unlike traditional metal ducts, fabric ducts don’t dent on impact, making them ideal for sports venues and halls. A stray ball can bounce off, and the duct will remain as good as new.

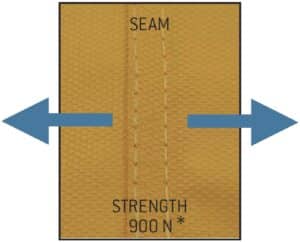

Strong seams and joints

It is said that a chain is only as strong as its weakest link. The textile joints of fabric ducts and diffusers, which are sewn seams, are crucial to their physical integrity. Our double-stitched flat-felled seams are designed to provide the strongest possible joints. With a tensile strength of 900N (for a 50mm specimen), any worries about the fabric joints can be safely dismissed.

Non-shedding, colour-fast multifilament material

Prihoda fabric ducts are exclusively composed of multifilament, endless fibre material designed especially for HVAC applications. Unlike fabric made with staple fibres, our material doesn’t shed, preventing localised thinning and surface wear. The result is a longer-lasting duct which looks brand new wash after wash. That’s how we can offer a 10-year warranty for our classic material.

Durability by design

All our fabric systems are bespoke and dimensioned precisely to the thermal requirements of each application. This allows us to use the most suitable and durable design choices in each case. Every detail is taken care of, from minimising local stresses at anchoring points to ensuring the right level of tension is applied for optimum performance.

Regardless of the type, all ducts require some maintenance to ensure proper performance over their usable life. Our fabric ducts are designed to prevent the accumulation of dust in the fibres. As a result, cleaning usually involves a quick wipe down or vacuuming of the external surface to remove any unsightly dust from the surroundings. If deeper periodic cleaning is required, such as in food factories and clean rooms, they can be laundered with a mild detergent in a washing machine. For ultimate convenience, we can take care of all maintenance with our in-house specialist laundry service.

If you want to know more, please get in touch.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us