Home / Fabric Ducting and Diffusers / Fabric Ducting / Special Products

Special Products

We use fabric ducting technology to create the best possible air distribution for almost any application. In order to do so, we have introduced some of the most advanced and innovative technical improvements in the fabric ducting space – we hold several patents, including for directional microperforations, adjustable large nozzles and our ground-breaking SquAireTex textile grid ceiling diffuser.

Get A Quotation Today

Insulated fabric ducting

Double wall and insulated for transfer ducting

The Prihoda insulated duct consists of an insulating layer of flame retardant polyester fibres sandwiched between two layers of flame retardant fabric. With a heat transfer coefficient of 1.8W/m²K, this is ideal for transferring warm air or air cooled below its dew point into the target area without affecting the temperature. Made in 2-metre sections between zips, this duct is available in diameters from 250mm upwards. This material is designed for air transfer and cannot be used with diffusers.

Recycled material

Fabric ducting made from used plastic bottles

Prihoda recycled fabric ducting is made from polyester that has been recycled from used plastic water bottles. With identical material properties, it’s impossible to tell the difference between our recycled product and our everyday product. So why not choose the most eco-friendly material for your project? Each recycled fabric duct uses 13 recycled plastic water bottles per square metre of material. We tell you the total in every quote, so you always know exactly what your project has saved overall. Our recycled fabric ducting is only marginally more expensive than the standard product, and it comes with all of the same excellent benefits of long warranty and flame retardant material.

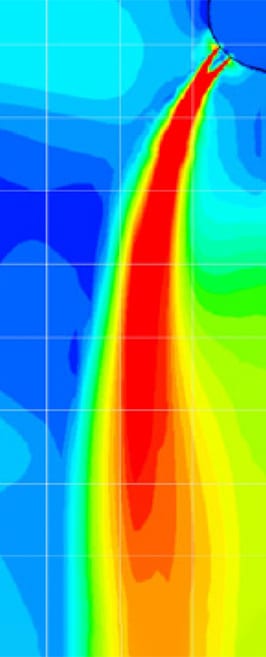

Airflow graphics

Velocity graphics with every quote – knowledge.

At Prihoda, we have developed our own quotation software, which includes visual airflow graphics with every quote. The graphics are specially prepared for each individual project and are based upon the type of diffuser, diffuser pattern, air temperature and the system pressure of the design. We want to make sure that our customers understand and have confidence in what is being proposed and have an opportunity to question or alter air patterns, if required. All our airflow graphics have been carefully calculated using our Ansys Fluent CFD software and then tested for efficacy.

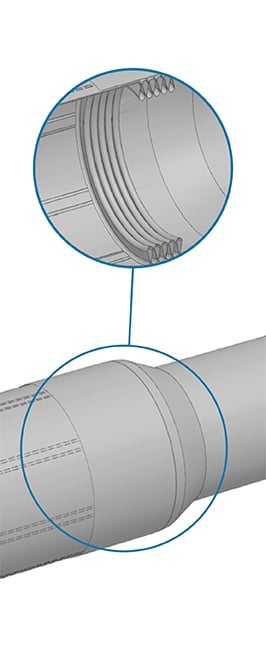

Adjustable length

Sections of fabric ducting with adjustable length

Occasionally on certain projects, it’s not possible to measure or predict the finished length of a system prior to manufacture. In these cases, we can provide a section of adjustable length fabric ducting so that the system can be manufactured and installed with some on-site adjustment available. (We can also do this with bends – see below). The duct can be adjusted between 500mm and 1500mm long (a 1000mm adjustment range). The adjustable section must be a diameter larger to make the pressure drop through the adjustable section acceptable within the overall design.

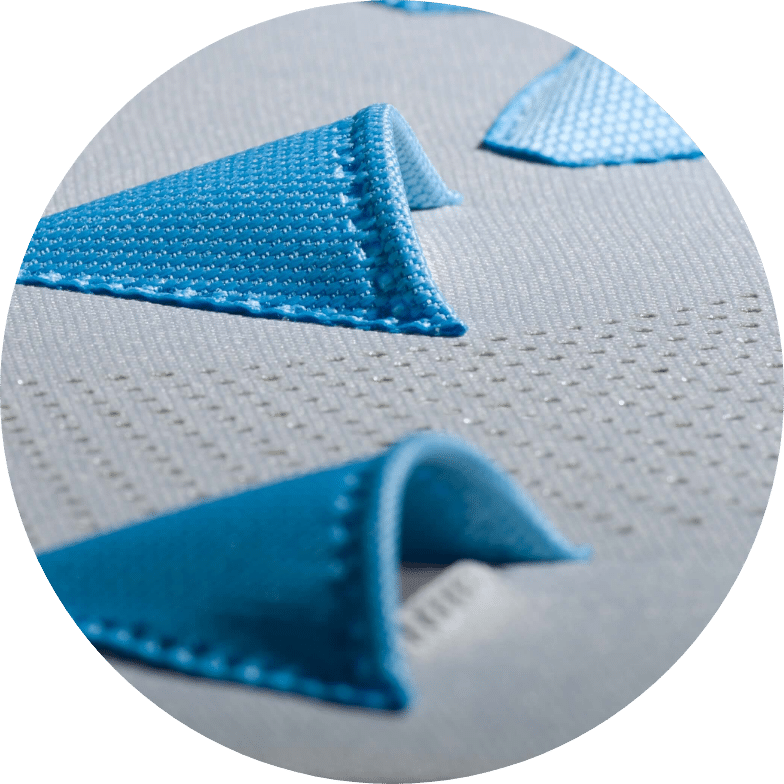

Micro-perforations

Low velocity – accurate air diffusion

Micro-perforations are an amazing innovation and allow us so much more flexibility than conventional permeable-only fabric ducts. The micro-perforations are 0.2mm laser-cut holes arranged in precisely calculated patterns to match the system design air volume and pressure.

They discourage duct blockage and therefore avoid pressure build-up, which leads to lower system efficiency and higher running costs in permeable ducts. We can choose exactly where to place these micro-perforations on the duct circumference, allowing us much more flexibility in terms of air distribution and delivery.

Anti-static

Inwrought carbon fibres for anti-static operation

There are a few anti-static ducts on the market, but they are anti-static with few other options. Our anti-static ducts are available in 9 different colours and are flame retardant and cleanroom compatible (ISO4). They are made with inwrought carbon fibres connected to earthing bands on the collars of the ducts, which in turn connect to the suspension rail system, ensuring a completely interconnected ducting system that can then be grounded by attaching to an earth wire.

Noise data

Noise data with every quote – knowledge

Along with the airflow graphics, our own Prihoda software calculates the overall noise data for each system, including inlets and bends. It automatically incorporates the data for each type of diffuser and the velocity and pressure within the system. This data is created for each individual system design and has been verified through laboratory testing at our R&D facility at Prihoda HQ.

Membrane diffuser

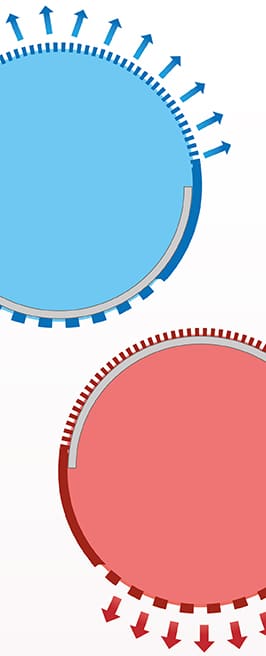

Extreme cooling and heating in the same duct

A clever design that allows two systems in one duct. A non-permeable membrane separates the top and bottom half of the duct without changing the effective cross-section in heating or cooling. On the top half of the duct, low-velocity diffusers allow the air to gently fall under its own weight into the occupied zone, as cold air has higher density. On the bottom half, larger diffusers positioned for maximum throw help the less buoyant warm air reach the occupied zone.

A motor positions the membrane to block the heating or cooling diffusers when not in use. Ideal for situations with quite wide cooling or heating temperature differences.

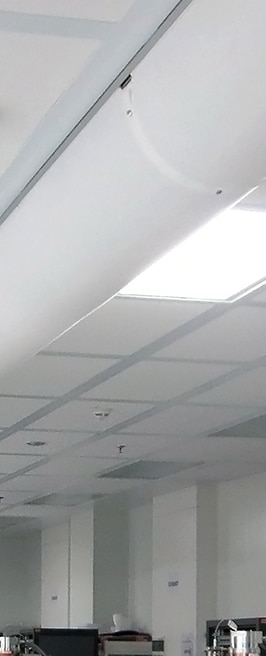

Prihoda SquAireTex diffuser

‘Drop in’ ceiling grid diffuser range

The Prihoda SquAireTex diffuser is designed to drop straight into a lay-in grid ceiling in exactly the same way as a traditional ceiling diffuser. Available in a range of distribution options, Prihoda SquAireTex is exceptionally lightweight – usually no greater than the ceiling tile replaced – and comes complete with a fabric plenum box, equaliser and stainless-steel clamp for the supply duct.

Prihoda SquAireTex comes with established airflow graphics and noise data and is available in a wide range of colours. Fully washable and with 2 years’ warranty, Prihoda SquAireTex is an exciting and advantageous alternative to traditional diffusers.

Fabric nozzles

Flame retardant small fabric nozzles

Small fabric nozzles are designed to throw air in a focussed jet in a specific direction. This is typically over a longer distance than laser-cut perforations. Nozzles typically entrain less ambient room air than laser-cut perforations. Prihoda fabric nozzles are available in 20mm, 30mm, and 40mm diameters, each giving different throw characteristics.

Fabric nozzles are made from the exact same fabric as the duct: same material and same colour. They are, therefore, flame retardant (unlike the plastic nozzles from our competitors) and, as they are sonic welded to the fabric, there’s no chance of them dropping off either. Fabric nozzles are also lighter than the plastic alternatives and cause less abrasive damage during duct washing.

Extract ducting

Negative pressure extract ducting

We are the only fabric ducting company to offer a production extract duct. Normally, we require positive system pressure to inflate the fabric duct and deliver the air. The problem with an extract (negative pressure) duct is that being fabric, it would just collapse. We stop this by installing the return air duct within a rigid frame designed to withstand the negative pressure effect on the duct. The frame keeps the duct in shape and in tension so that, aesthetically, it continues to look good as well as work well.

Available in all 9 stock colours and in exactly the same material as our supply air fabric ducts.

Adjustable bends

Fabric modular system with additional flexibility

As with our adjustable length fabric ducting, we also offer an adjustable flexible bend for situations where the exact bend angle isn’t known prior to manufacture. We use a series of internal strips which, when pulled taut on one side and released on the other, create the bend in the direction and at the angle required. The bend is typically zipped on either end, so you can install it easily and/or use it to establish the correct details to have a fixed bend manufactured at a later date.