Office Ventilation

Get a Quotation Today

Problems with air ventilation in offices

Office building environmental air systems commonly experience several problems with air movement and temperature. Here we look at the 5 most common issues and how Prihoda fabric ducting can help you solve these problems.

Benefits of using Prihoda Fabric ducts for Office Ventilation

1. A lack of air movement.

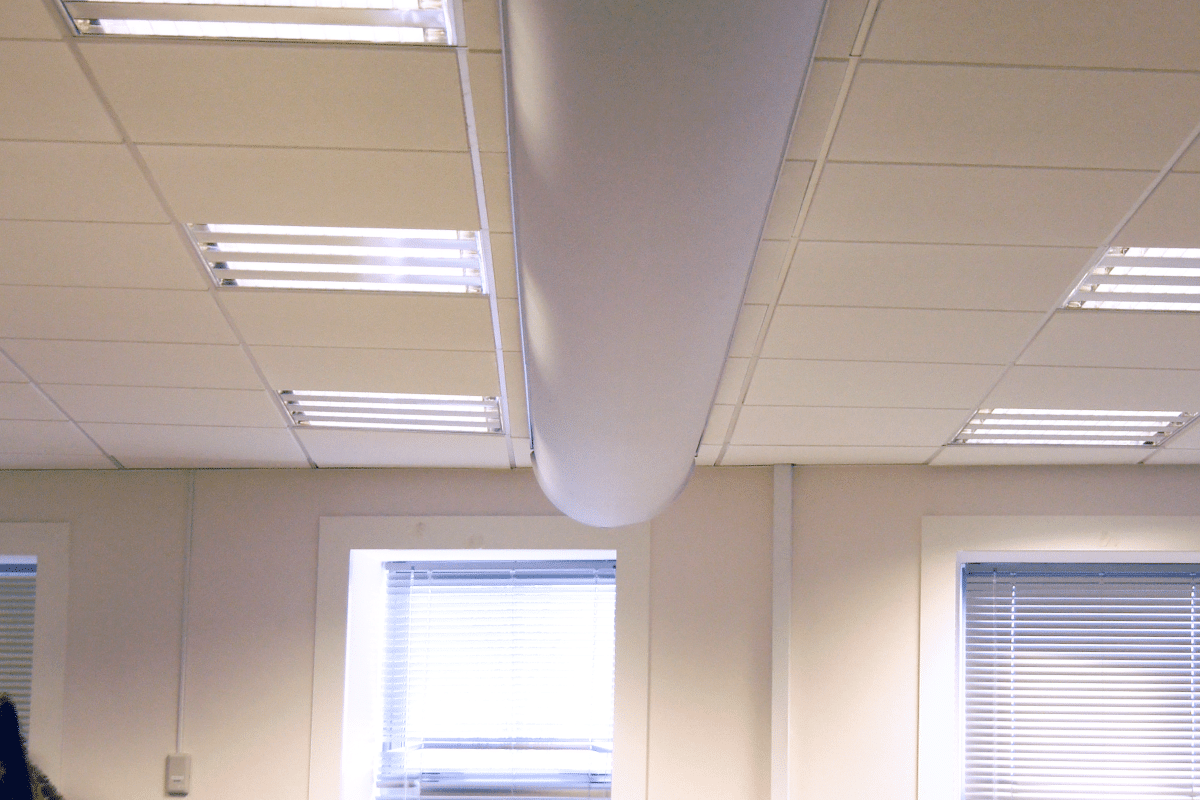

Often caused by insufficient air volume or, more likely, poor distribution of air within the space, so that parts of the office building are getting no fresh or recirculated air at all. Stale air leads to occupant tiredness and illnesses and can create the situation known as sick building syndrome. Buildings with ducting above the ceiling have a few diffusers dotted around the room, and we often hear of complaints about draughts and poor circulation. A Prihoda fabric duct is installed so that the entire surface of the duct is in the room. The whole surface can be permeable and leak air through the entire surface area and all along the duct. We often also make this flowing air ‘directional’ as it leaves the duct so that we know it’s heading towards areas with little or no circulation.

3. Noise

Large systems of rigid steel ducts pushing air through small rectangles of diffusers cause draughts, as we’ve discussed, but with this velocity comes noise. Systems like these are made from rigid materials and can often reverberate and generate noise within the system’s ducting. Prihoda fabric ducts are made from fabrics that are flexible and can absorb vibration and noise. We provide a noise calculation for each and every quotation, as we design our systems around each specific application. If we know we’re designing an office system, we produce the quietest air delivery system possible, acceptable for labs, offices, libraries, theatres and, importantly, film and sound recording studios. The slower the air velocity, the quieter the duct.

5. Sustainability

Perhaps one of the most important factors in today’s world is the question of sustainability. This can be summarised as follows: How much raw material did the product consume? How much energy did it take to make the product? How much energy did it take to ship it? How recyclable is the product once its useful life is finished? Prihoda’s Repreve recycled fabric ducting is one of the most sustainable building products on the planet. The material is 100% recycled. The recycled material has come from used plastic water bottles – 100% POST-CONSUMER recycled material Each square metre of material used saves 13 bottles (500mm) from landfill The manufacturing process uses: 100% less raw material 66% less energy consumption 50% less water consumption 40% less greenhouse gas emissions

2. Velocity

Draughts are one of the most common complaints in office ventilation. Cold air is worse than warm air, as it causes a stiff neck and can even lead to time off work for some employees. The constant stream of air at a noticeable velocity (say, more than 0.35- 0.50m/s) is stressful and creates situations where it can be hard to concentrate – in a very similar way to noise problems in an office. In a typical office ventilation set-up without fabric ducts, there’s lots of steel duct in the roof and only a few penetrations in the ceiling for metal diffusers. These diffusers must deliver a lot of air through a small area and often in multiple directions. As a result, they create high-velocity air patterns that affect people at their desks. Often desks are moved, or offices get refurbished, but these large, expensive steel systems stay the same. Cassette air conditioners also create these issues. They deliver fast streams of cold air that travel a long distance due to their density, as cold air is denser than warm air. We have actually developed a line of products to help solve that specific problem.

4. Cleaning

Traditional office ventilation systems are difficult and expensive to clean. Dust will eventually settle into any duct: all ducts should really be cleaned after a 5-year operational period, metal or fabric, purely from a hygiene perspective. Fabric ducts simply slide out the rails and can be washed directly in a washing machine at 40oC. Available in 9 colours as standard, our ducts are colourfast and will look brand new wash after wash.

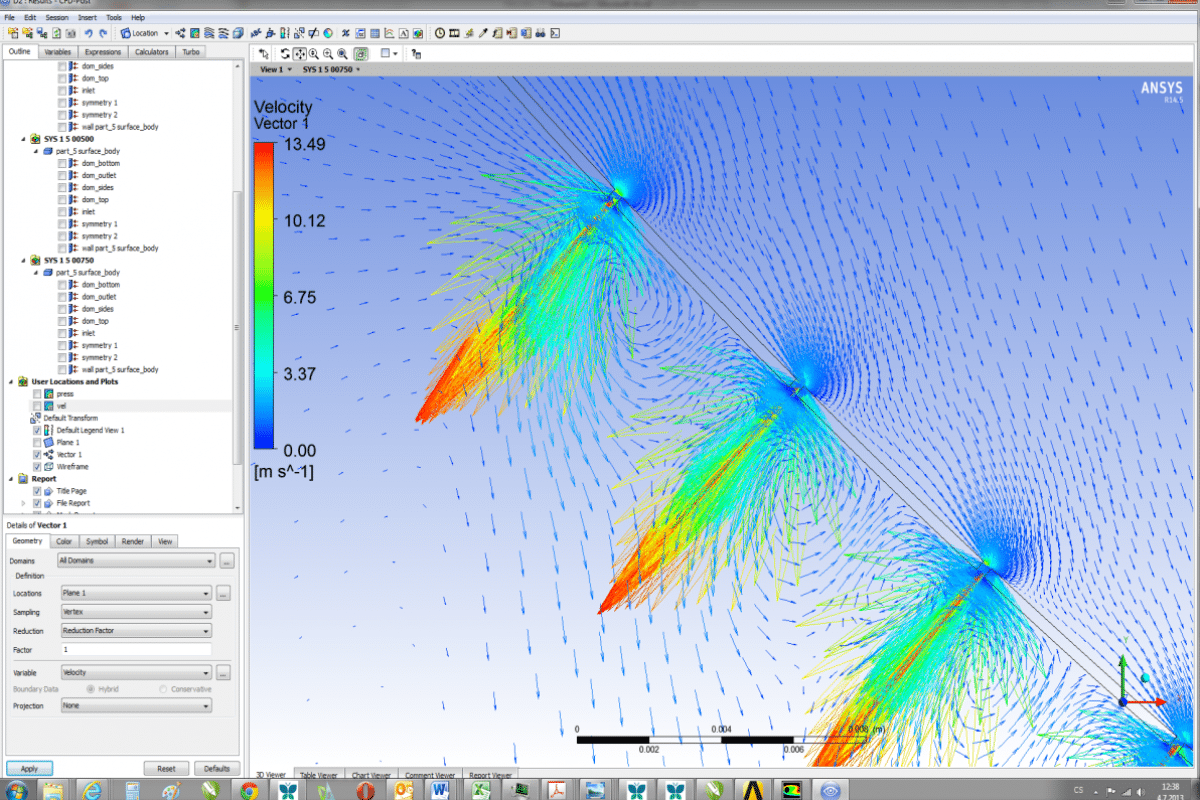

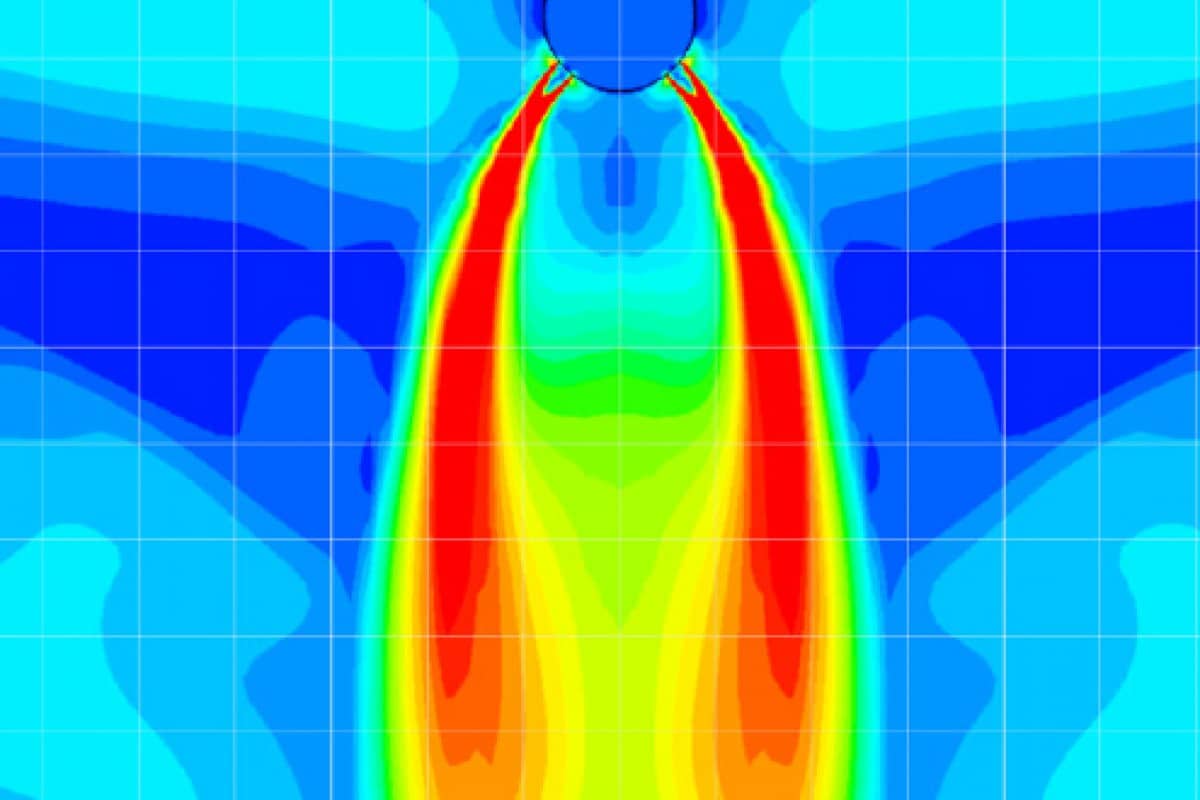

Airflow Graphics

Prihoda fabric ducting is designed to deliver large volumes of cold air at low velocity into the occupied zone. Our micro-perforation technology – developed by and unique to us – encourages a lot of mixing and entrainment of surrounding room air. It delivers the cool conditioned air exactly where it’s needed and always at low velocity. We are the only fabric ducting manufacturer to produce airflow graphics specific to each individual project as standard. We have a state-of-the-art research and development facility and use Ansys Fluent software to predict the characteristics of each tiny laser-cut perforation.

Do you have any questions?

Our experts are on hand to help. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us