FAQs

Yes. In certain circumstances we will be able to offer a Prihoda approved installation. This ensures that the duct is installed to the best installation practices and recommendations. Our installation teams have all the necessary site qualifications and certifications. They are also certified and qualified to operate a wide range of plant and installation machinery.

We would visit site to survey and create the necessary H&S documentation and co-ordinate the installation ourselves. We work unsociable hours and weekends and this service includes removal and reinstallation for cleaning if required. We don’t offer installation on every job; it is project specific. Please contact us for details.

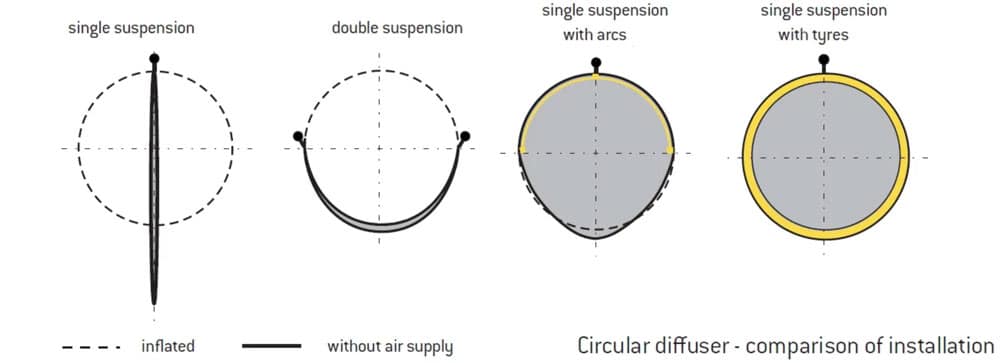

The Fabric Duct system can be designed to take on a variety of shapes to suit the circumstances, by either using additional support rails or by adding rings that maintain shape when the duct is deflated.

This is difficult to answer as it depends on the environment in which they are installed and how well they have been installed and are looked after. Most of the materials we supply in the UK have a 10 year warranty so we would expect 10 years life as a minimum. The material is rugged and has been developed and made specifically for the job, it is very unlikely that the Fabric Duct is going to tear or come apart at the seams for many years after warranty has ended unless it is subject to abuse or hostile conditions we were not aware of.

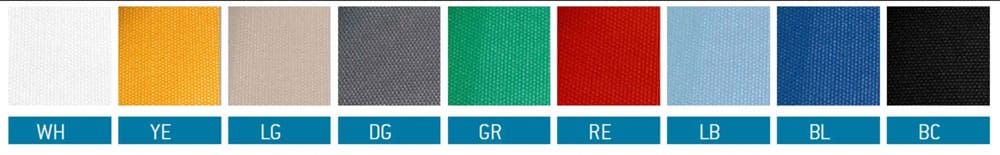

There are 9 stock colours with our standard and premium products all of which are available at no additional charge. Our Recycled Fabric Duct is available in 4 colours as standard (White, Light Grey, Dark Grey and Blue). Non standard colours and printing on the ducts are also available at additional cost, please contact us for more information.

It’s pretty much the same as rigid duct. We don’t like to go higher than 8.0m/s if possible, but generally we’ll design at velocities much lower than that for most non industrial applications and of course 2.0m/s or less for really quiet areas. We provide noise data calculations for most selections so it’s easy to relate velocity/diameter/noise within a quotation and make any alterations required. Please talk to us about velocity and/or design questions if you have them. Please also note we have a CIBSE certified CPD course available for basic Fabric Ducting design and selection.

In a well designed straight diffuser there is almost constant static pressure throughout. The laser cut perforations are calculated (size/quantity to create the diffusion area) to match the available static pressure. In other words the Fabric Ducting system is designed based upon the available static pressure of the system. Bends and other shaped pieces create losses which need to be taken in account (we do that automatically within our system design). Loss due to friction is usually minimal due to the decreasing air speed inside the Fabric Duct. We normally require approximately 125Pa – 150Pa available external static pressure at the duct to accommodate the systems requirements (inflation, losses, air delivery). But we can accommodate pressures much lower if required by changing the designs or materials to suit.

Please refer to the Maintenance and Warranty page for further details on washing and maintenance.

Yes we do. This is usually rectangular and held in shape with a rigid suspension system…. please see further details on the Innovations page and also contact us for further information and a selection.

Typically a Fabric Ducting system is designed to match the volume and pressure of the AHU system. It’s designed to deliver a certain volume of air for each branch which has been designed and calculated as part of the overall system design. Assuming no branches to other systems or non fabric diffusers exist within the system then the fabric ducting system will self balance. If there are other types of diffusers (Grilles for example) you will need to install dampers to control the air volume to the separate parts of the system.

As every duct is made to order average delivery time is about 3 weeks from date of agreed design following order – plus a day or two shipping. During winter months when there is less production pressure this may reduce to two weeks delivery time. Conversely during summer we may be quoting 4 weeks delivery as this is our busiest time. We generally try to ensure we never exceed a four week delivery window.

It makes a lot of sense to order the suspension system to arrive before the main Fabric Ducting system, especially if you have access at the time or time is tight on site. We can usually accommodate this request but we do charge a small amount extra to cover the additional delivery cost. If there are some special items in the suspension design that need to be manufactured as opposed to being delivered from stock (specifically swept elbow suspension) then these will usually be delivered with the main Fabric Ducting system later.

Do you have any questions?

Our experts are on hand to help. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us