Green Building with Fabric Ducts and Diffusers

What is Green Building?

A ‘green building’ or sustainable building is designed to be as kind to the environment as is practical with current technology, construction techniques and materials. As a design and construction philosophy, green building aims to:

- produce sustainable buildings which require fewer resources to construct and maintain,

- protect the health and wellbeing of its occupants,

- release fewer pollutants into the environment,

- and have an eco-friendly lifecycle, from component manufacture to end-of-life decommissioning.

Why use Green Building?

We must all play our part in the protection of the environment. Yet architectural and construction materials and processes have played an outsize role in the destruction of habitats worldwide. For example, concrete, the most widely used construction material in the world, is also one of the most polluting, releasing 822 kg of CO2 for every tonne of cement used to make it. Similarly, many common construction materials are difficult to dispose of sustainably at the end of their usable life. It stands to reason that using an eco-friendly, green building approach goes a long way towards helping the environment.

From a purely practical and business perspective, it also makes sense to use sustainable building techniques. By ensuring resource-efficient construction processes, architects, planners, and specifiers can save on building costs without compromising on quality. And with increasingly stringent environmental protection laws, this is expected to become an even more important business requirement in the future.

How to make a building ‘greener’?

Green building can be achieved through a combination of design, materials and processes. There is a wide range of opportunities for more sustainable construction, and each case is highly individualised. Typical choices in new buildings are:

- Locating and positioning the building to take advantage of natural resources such as sunlight and wind.

- Designing for net zero carbon; for example, by measuring the embodied carbon in construction materials and offsetting their emissions.

- Reducing the operational energy requirements of the finished building by selecting efficient building services and utilities.

- Using materials sourced sustainably with a responsibly-managed lifecycle.

Older buildings, which were rarely designed with sustainability in mind, can also be adapted to waste fewer resources. Draught-proofing, improving their insulation to minimise heat losses, and retrofitting modern energy-efficient heating systems are some commonly used ways to reduce the environmental impact of older buildings.

Are Prihoda fabric ducts ‘green’?

Yes! Our fabric ducts contain over 90% less embodied carbon than a typical equivalent galvanized ventilation duct. The lifecycle environmental performance of our fabric ducts and diffusers has been independently verified to achieve Type III EPD according to ISO 14025.

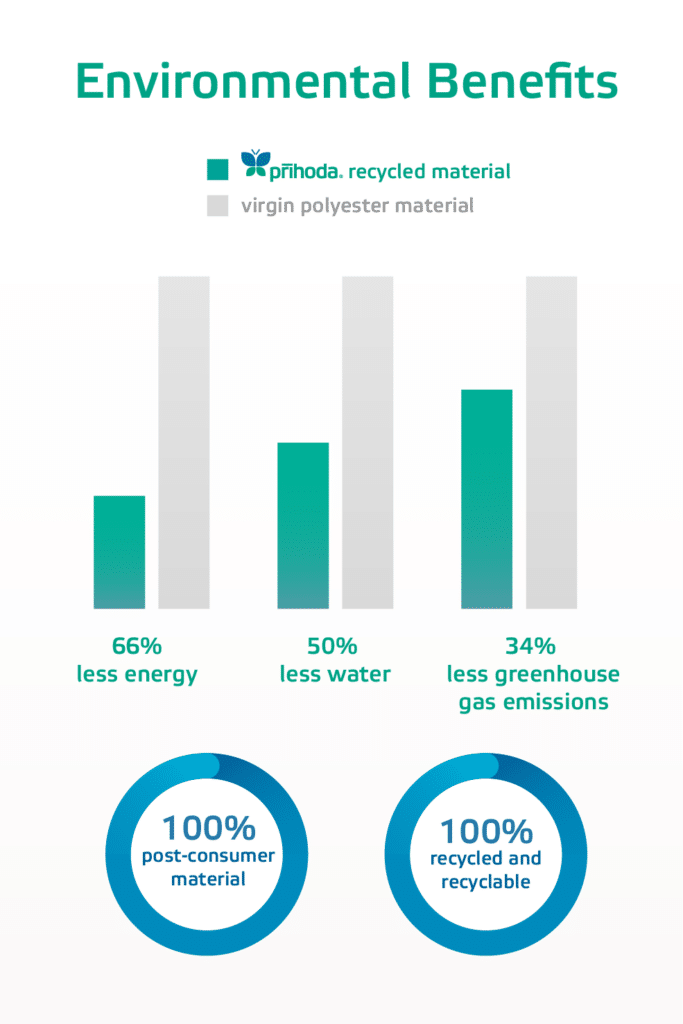

Our recycled fabric ducts are made of one of the most eco-friendly building materials in existence. They are made using Repreve® yarn, made from recycled plastic bottles thrown away by consumers. The bottles are collected, sanitized and processed into spun fibres which are then used to manufacture our recycled fabric ducts. By using post-consumer recycled material, we can save energy consumption by 66%, water use by 50%, and greenhouse gas emissions by over 34% compared to virgin material.

All our products are certified Standard 100 by OEKO-TEX. This global standard guarantees that our fabric ducts are free from over 100 substances known to be harmful to human health, such as pesticides and heavy metals. As a result, Prihoda fabric ducts are an excellent choice for green building, while helping to prevent sick building syndrome.

Much has been said about microplastic pollution. Our textile ducts are made with endless fibres and are certified for use in cleanrooms to ISO Class 4, which means they don’t shed fibres and therefore don’t release microplastics into the environment. As they are fully recyclable, the material can be recycled and reused again and again to make new fabric ducts or other products.

Please get in touch if you’d like to know more.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us