Micro-Perforations in Fabric Ducts

Micro-Perforations in Fabric Ducts

How do Micro-Perforations work?

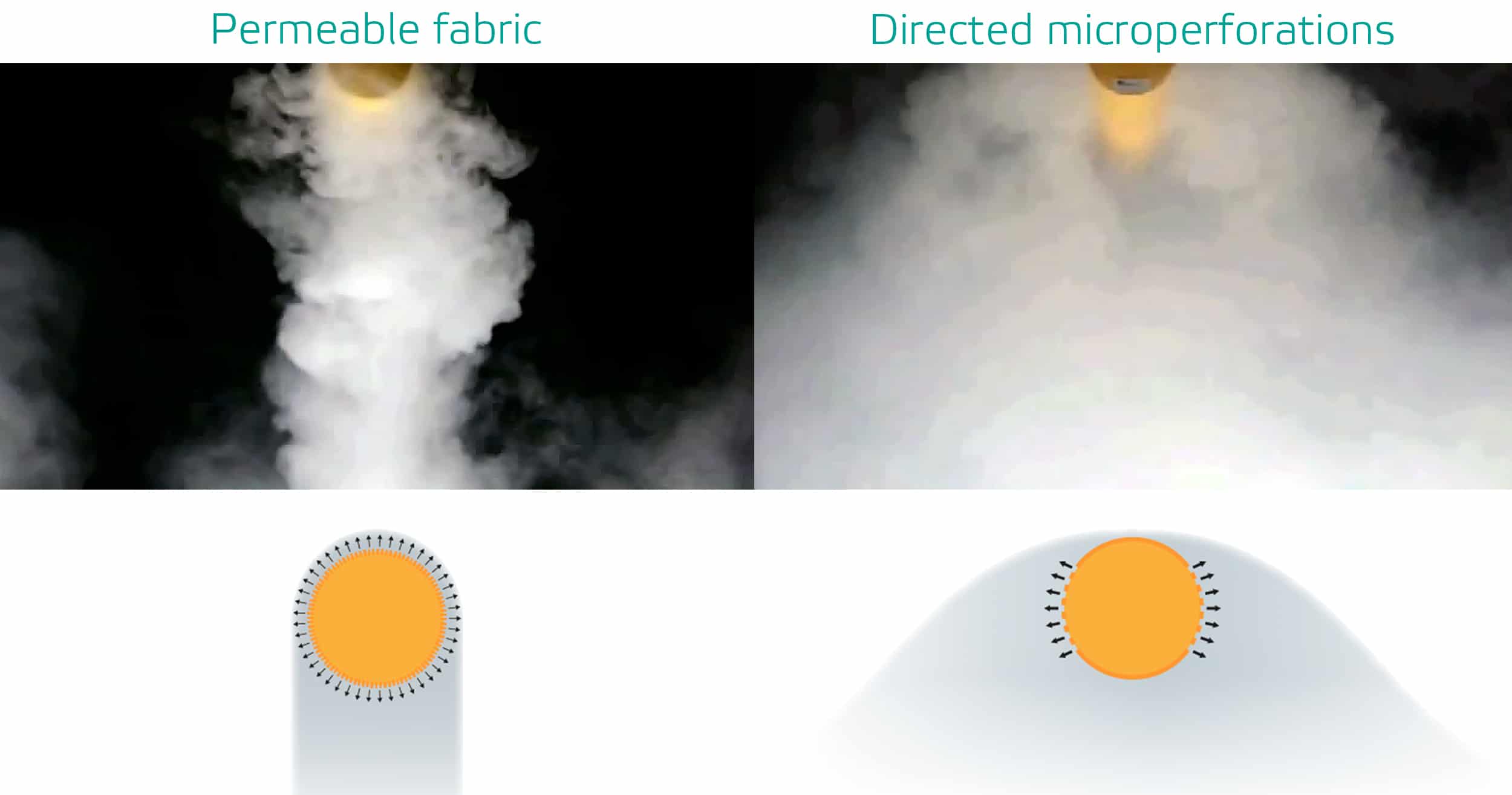

Micro-perforations are an amazing innovation and allow us so much more flexibility than conventional Permeable Only Fabric Ducts. Originally, fabric ducting companies squeezed air through the weave of the material when cooling, but this creates issues with dust blockage. In order to stop squeezing the air through the material to avoid this problem we need another way to deliver the air at low velocity. For this we developed the micro-perforation diffuser – a patented product for Prihoda.

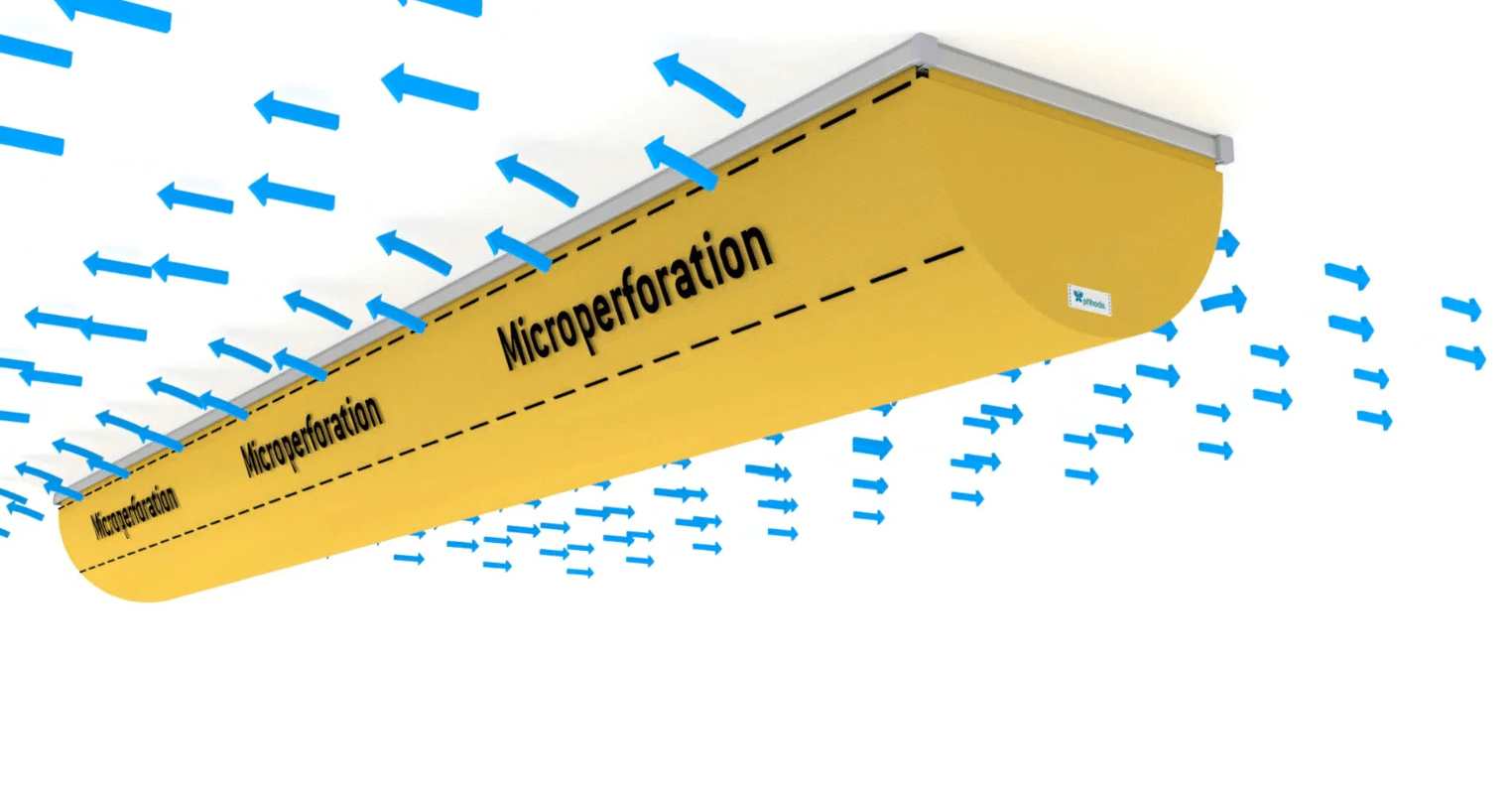

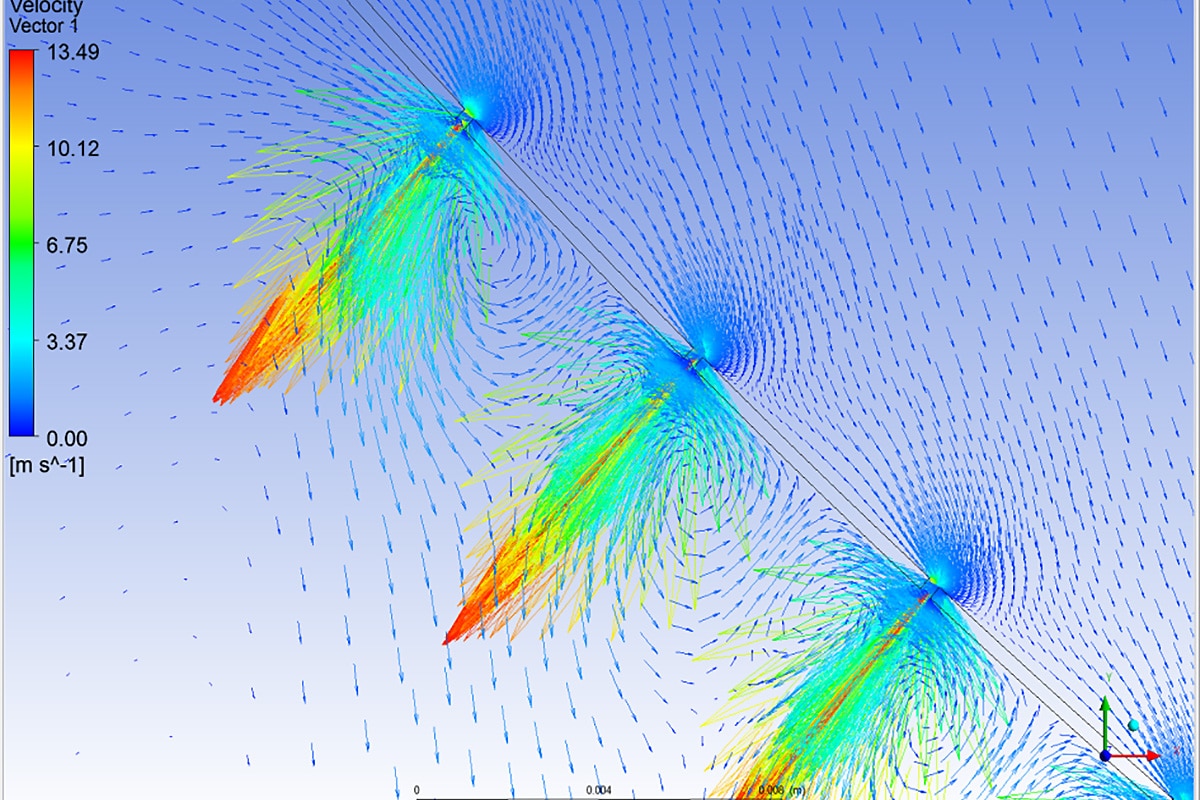

Essentially, micro-perforations are tiny 0.2mm or 0.4mm laser cut holes within the fabric material. Knowing the area of each micro-perforation we can easily determine how many micro-perforations are needed for each system. So this gives us a precise diffusion area so that air is delivered consistently at the designed system pressure.

Why is Prihoda material so different?

Some of the first fabric diffusers were used in the food industry. Hygiene regulations require that all food processing devices should be easily sanitised and cleaned. Out of all the air distribution system options, this condition is only met by fabric ducting. Fabric ducts are perfectly clean after washing and a disinfecting agent can also destroy any pathogens that may resist the antibacterial treatment.

Fabrics made of endless fibres, developed especially for Prihoda‘s textile diffusers, are very smooth and do not allow the build-up of impurities. This unique and special feature distinguishes them from diffusers made of staple fibres that continuously trap dust and can represent a sanitary risk. This also means that our fabric ducts are Cleanroom Standard (ISO4 – Class10).

Every system we make with our classic materials is cleanroom standard and available in the full range of 9 colours at no additional cost.

Better Distribution.

Micro-perforations also create another benefit, much better air distribution. Traditional permeable ducts squeeze cold air through the weave of the material. So that, once it leaves the duct it falls under its own density, effectively dumping all of the air beneath the duct. With micro-perforations, we can laser cut the perforations wherever we wish on the duct. This is usually done in bands along the sides to spread the air and create better air distribution even at low velocity. Air is no longer dumped below the duct in a column, but spread more evenly all around the area of the ducting. We call these directional micro-perforations.

Take a look at the videos to see micro-perforations working.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us