Vertical Farming HVAC Systems Design With Fabric Ducts (Part 1)

Prihoda has gained quite a lot of experience with vertical farming systems over the last few years. In this blog post, we will look at how fabric ducting can be used in vertical farming operations to help create the right growing conditions for the plants and crops being grown. But first, let’s look at what is vertical farming.

What is vertical farming?

Vertical farming is the process of growing products indoors in a controlled environment whilst using LED lighting and hydroponics. The plants are grown in trays, often stacked in racks multiple layers high.

The benefits of vertical farming include:

- Crops all year round, so that products are available out of season

- Good growth through environmental control

- More efficient disease control

- Higher yield per square metre

- It uses less overall area, as growth is vertically orientated in multiple layers

- Lower transport cost for products grown and consumed locally

- Consistent product quality

- Easier to produce organic products without the need for pesticides

- Potentially less food waste, as production can be planned around demand.

For these reasons, it’s quite a ‘growth’ industry (do you see what we did there?), which has developed rapidly in the last few years.

Having designed and provided systems for several dozen different projects, the one thing we’ve learned is that no two vertical farms are the same. They all differ enormously, with their own HVAC system design, racking layout and differing levels of sophistication for harvesting. For example, we have worked with an Italian manufacturer who uses a fully automated harvesting system with mechanised rack removal so that no-one need go into the space unnecessarily. We also know an early pioneer that sells fish and uses the water and ‘digestive waste’ from that product for the hydration and nutrients required in the Vertical Farm.

HVAC systems design for vertical farms

So far, we’ve come across two principal ways to design the environmental control for the growing beds:

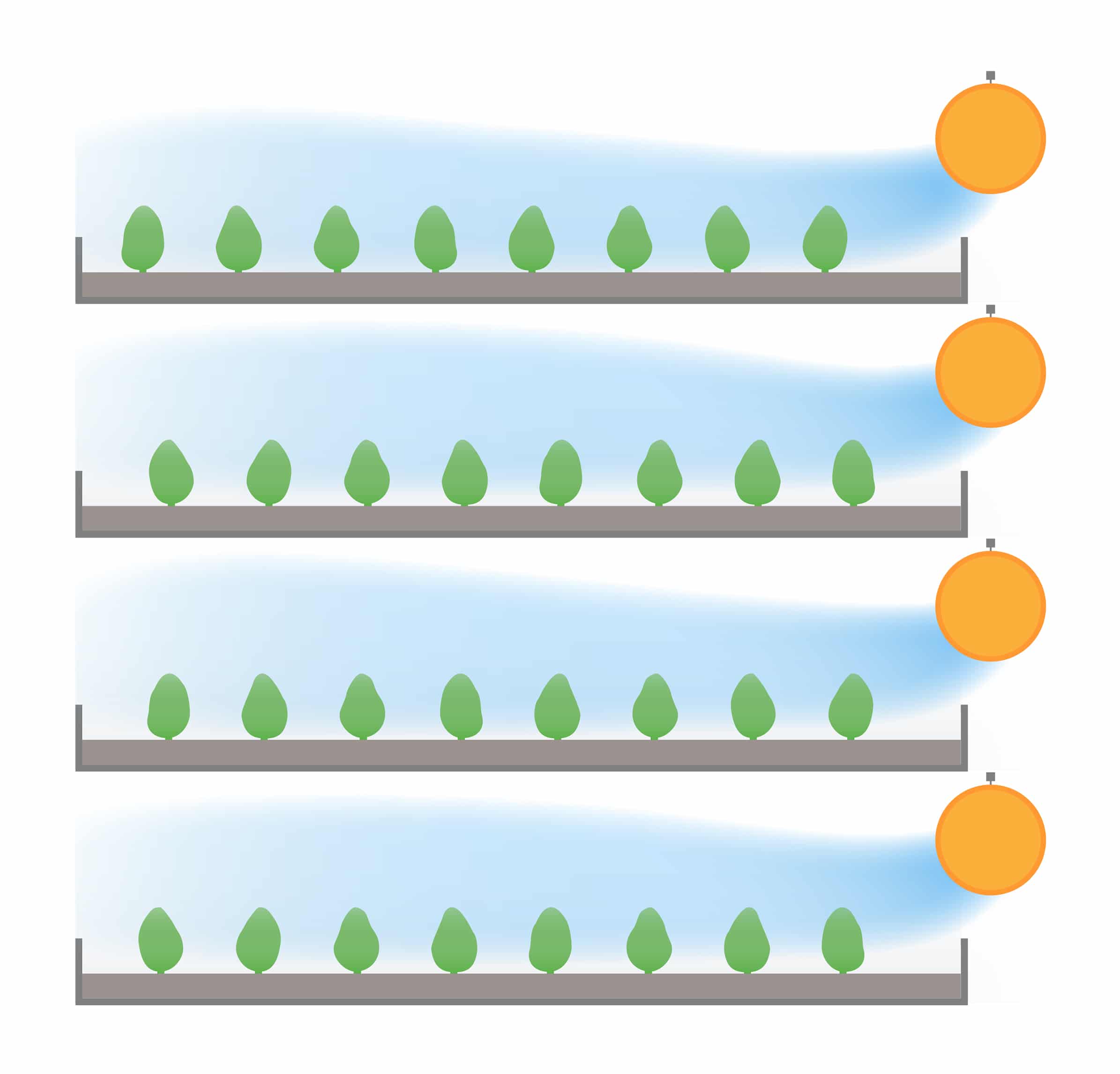

Type 1: The main HVAC system controls only the air delivered across the growing bed directly over the plants (connected directly to the fabric ducting).

Type 2: The HVAC system conditions the whole space and uses secondary fans at the beginning of each rack to supply the air into the fabric duct and over the plants.

Unfortunately, we don’t have data on which works best, but there are advantages to both.

Type 1 delivers conditioned air through the fabric ducts without controlling the room temperature directly. It can have a smaller energy requirement than the alternative set-up because it only controls the air volume of the racks, requiring less energy to create the correct environment around them and resulting in lower capital and running costs. However, as this is a central system, all racks receive the same air volume at the same temperature.

Type 2 conditions the entire space and then has small secondary fans at the beginning of each rack to inflate the fabric ducts and provide air over the growing beds. Although a larger design in terms of cooling or heating capacity, Type 2 can be less complex than Type 1, as it only needs to get air into the space. This can be done relatively simply – only the smaller independent fans and the fabric ducting are concerned with creating the correct conditions around the plants. The benefit here is that one can speed control the fans and create a different air pattern independently across each bed. This allows for the possibility of growing different products at different rack levels and/or starting and harvesting products at different times in the same facility.

Which layout works best?

We consider the Type 2 system ideal for R&D, as it can be used to create the conditions necessary for a range of plants and growth speeds. For scale production, however, Type 1 is probably the better system, allowing a single product to be grown and harvested at the same time in each space.

Both system types work perfectly with fabric ducting. The fact that it’s always bespoke makes it easy to create the required layout, regardless of how the vertical farm is actually set up. We tend to use permeable material due to the high humidity levels generally present in any crop growing operation. This way, we can prevent undesirable condensation on the ducting (which can become a source of microbial contamination) even with cooler supply air, as is usually the case in vertical farming.

As we have seen, every vertical farm is different, with different approaches to how they grow the plants, processing, layout, and even HVAC design. At Prihoda, we have designed fabric ducting for a wide range of vertical farms. Our experience enables us to understand what’s required based on the initial vertical farm layout, its operation, etc. Fabric ducting works very well with the two main types of HVAC design for vertical farming, whether it is used for the main air delivery in the room (as in Type 1), or only as secondary air delivery systems just for the growing racks (as in Type 2). As with all our designs, we are happy to provide advice to help you achieve the ventilation solution you need.

This is part one of a two-part series on vertical farms. Stay tuned for the second part!

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us