Vertical Farming HVAC Systems Design With Fabric Ducts (Part 2)

Vertical farming is a much more efficient growing method, providing high crop yields even in limited space, such as cities. The growing trays containing the substrate are set up in layers, with stacks of trays taking up very little floor space. The plants grow in a controlled environment, preventing disease propagation and making it easier to grow them organically without pesticides. Not surprisingly, it is a rapidly growing farming approach around the world.

In the previous blog post, we looked the use of fabric ducting in vertical farming and the two different types of HVAC systems commonly used in vertical farming operations. To recap, they are:

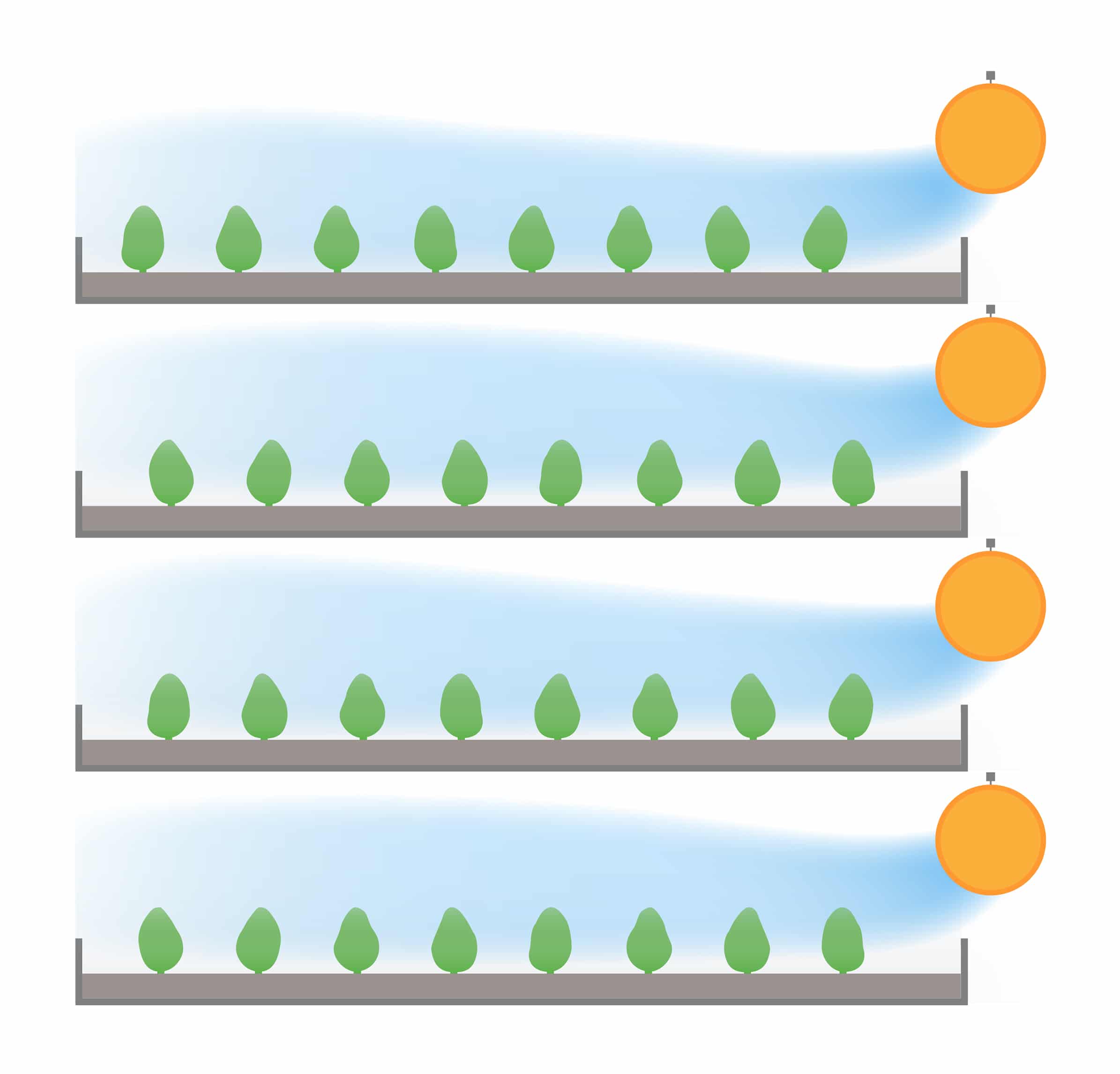

- where the central HVAC system controls the air that moves over the plants through the fabric ducting, and

- where the plants rely on secondary fans located at the beginning of each rack, connected to the fabric ducting.

But it’s important to also consider how the air will be distributed throughout the growing beds.

Air Movement in Vertical Farming

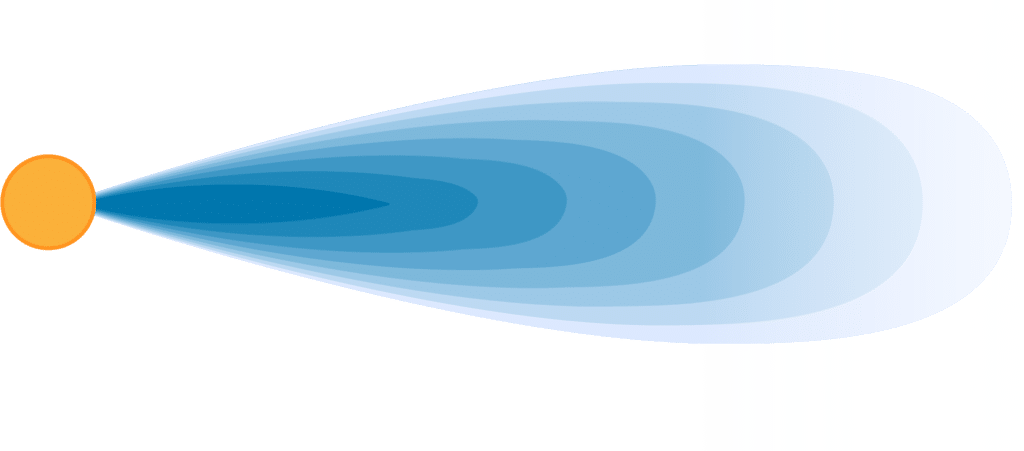

Although not totally exclusive, the primary method of delivering air to the growing bed is to place the fabric duct at the side of the racks and running along their length so that the duct throws air across the growing beds.

The air across the growing bed is usually cooler than the room’s ambient temperature, and its velocity varies according to its temperature. With the Type 1 system, where the cooling is delivered directly through the fabric ducts, we generally keep the velocity out of the duct at around 0.7m/s to avoid damaging the leaf of the product. With Type 2 systems, the whole room is at the same temperature, and the velocities can usually go a little higher if desired if the plants are robust enough. Since the ducting is designed bespoke, we can finetune the distribution accordingly.

Particular attention needs to be paid to the growing bed’s width in the direction the air will travel (widthwise across the rack) and the density of the mature plants. The air only has a finite amount of energy to travel across the deck, and it is slowing down (and warming up) the whole time. Growing beds wider than 1.2m can quickly lose their velocity, and travel through the plants becomes difficult to predict. Wider growing beds usually require higher air volumes and a little more pressure. Air direction can be encouraged by using the extract system, but the mechanics of this need to be carefully considered.

LED lighting gives off heat, which also needs to be allowed for within the HVAC plant’s energy requirements calculations. There are various strategies for removing this, using rack positioning and fabric ducting supply, or general extract positioning.

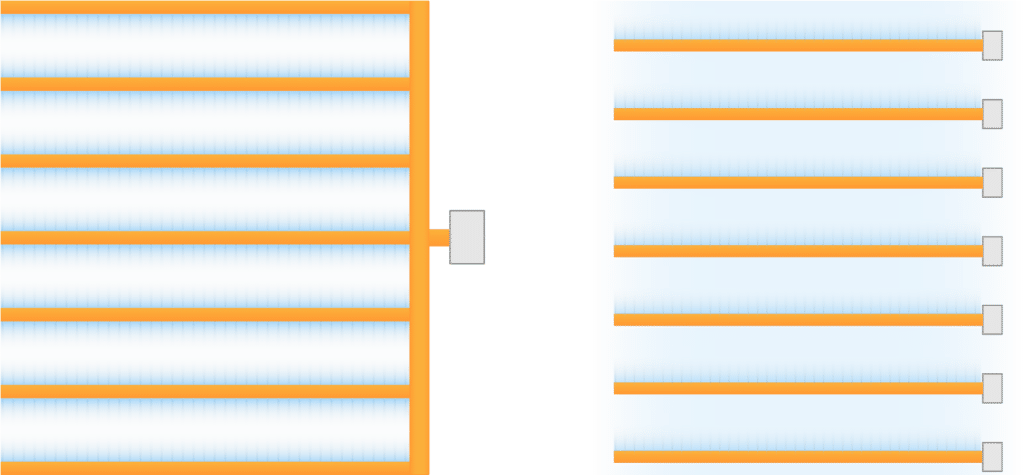

The actual amount of air used for each duct depends upon which type of HVAC has been chosen and how much air is required to overcome the heat load of the space. It’s not unusual to have more than 30 x air changes for the volume of the growing beds, but each case is different. As discussed above, wider growth beds can result in higher air volumes and greater air change rates. This is the beauty of using fabric ducting for this application, as every fabric duct is designed and made to order – there is no stock product.

We usually make our ducts from permeable material with antibacterial treatment. The antibacterial treatment is a precaution to ensure anything that comes into contact with the duct material is sterilised. Additionally, it helps to inhibit mould growth should these conditions occur. Our products have a long warranty and multiple options, including recycled material.

To go back to the introduction, no two vertical farms are the same. Whilst we are not horticultural specialists (we have plastic plants in the office) we understand what will be required once we have seen the initial layout of a vertical farm design. When it comes to the air movement over the plants, we can provide advice and selections with airflow graphics for many different temperatures and conditions.

Please feel free to contact us for an informal chat about your project.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us