Animal Housing Case Study

At Prihoda, we design and install fabric ducting for a wide range of commercial and industrial applications. Kitchens, sports centres, warehouses and many others make up most of our work. Occasionally, a more unusual project comes along, like this one.

The Challenge

Prihoda was asked to design new replacement fabric ducting for a cattle barn. The existing design used polythene tubes for this purpose, but they presented some problems which could be overcome by switching to Prihoda’s fabric ducting. For example, the PE tubes could get soiled easily in the dusty conditions commonly present in animal housing. The antibacterial treatment available with fabric ducting was also a desirable feature for this application.

Our Approach

This is an unusual project in that most fabric ducting projects must consider the comfort of human occupants rather than occupants of other species. Cattle have their own ventilation requirements. While adult cows aren’t very fussy about draughts, they do prefer slightly cooler conditions. With calves, an excessively cold environment forces them to eat more and use the extra energy to stay warm – at the expense of their growth and the owner’s profits. Our fabric ducting needed to supply adequate ventilation for the cattle barn’s maximum capacity of 100 animals.

We addressed these requirements using several rows of 6mm laser-cut perforations to direct the air towards the animal enclosure. The duct was created using our lightweight material. At only 80g per square metre, it is designed for applications where the weight of the ducting must be kept to a minimum, for example, where the building’s structure is very lightweight. It is also suitable for temporary applications such as marquees.

The Outcome

As with all Prihoda fabric ducts, the test duct was designed fully bespoke, considering the barn’s dimensions, the type of ceiling, the airflow requirements and occupant comfort. It perfectly demonstrated the excellent performance of fabric ducting in agricultural applications.

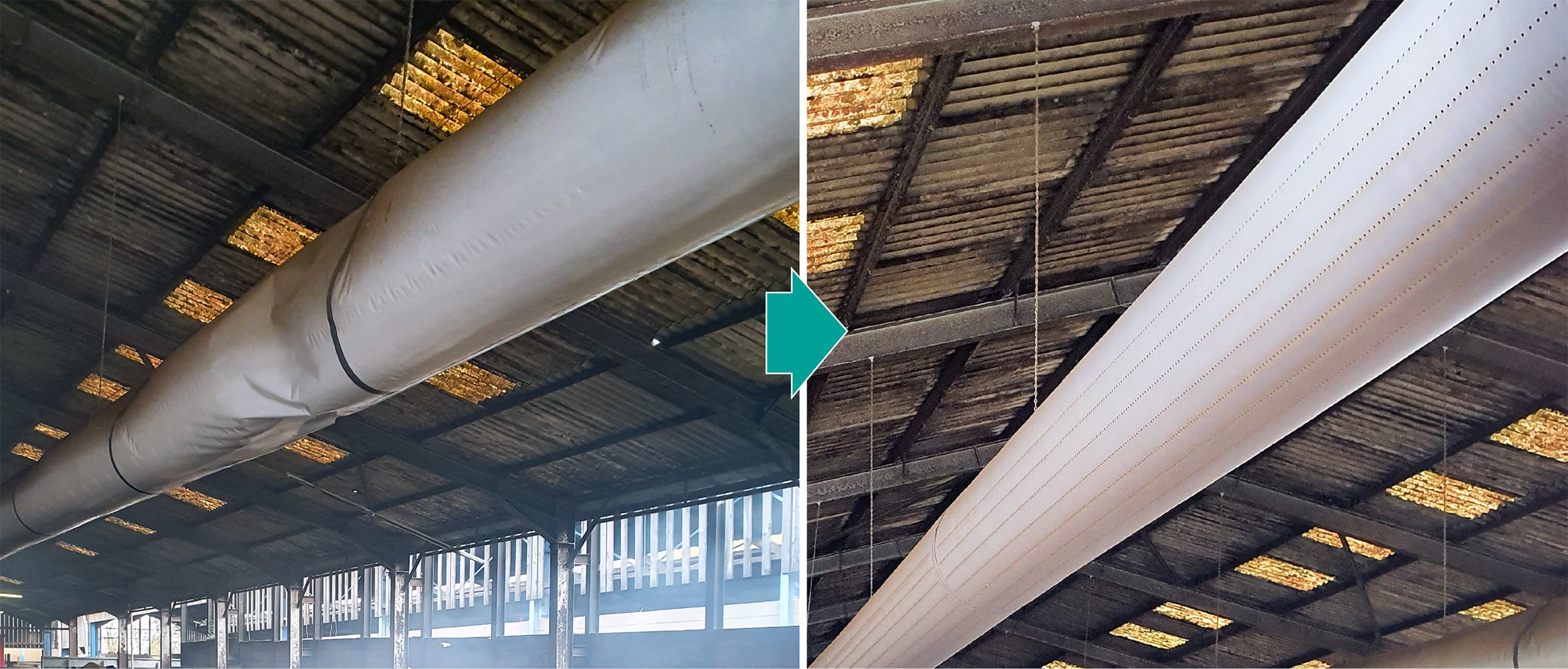

While this project didn’t focus on aesthetics, the new ducting looked neater and more visually appealing than the previous ventilation solution. For example, the darker bands and deformation visible in the older tube aren’t present in the new fabric duct.

Despite being in a dusty environment, the duct’s performance doesn’t deteriorate over time, as there is no airflow through the weave of the fabric. The material is impermeable, and all the air is distributed through precisely cut perforations designed to deliver it where it is needed most. This also makes it easier to clean – a quick surface wipe is all that is typically required. For more thorough cleaning or disinfection, all our fabric ducting is suitable for machine washing at low temperatures, with or without disinfection treatments.

The result is a clean, neat fabric duct that provides the right airflow conditions for this cattle shed.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us