Directed Microperforations – A Unique Prihoda Innovation

At Prihoda, we are always striving to achieve the best possible HVAC solution with fabric ducts and diffusers. Whether it is keeping the air fresh and healthy in offices, ensuring cleanliness in food manufacturing, or providing comfortable ventilation in hospitals, we are continually developing new ways to make it happen. Directed microperforations are one of our patented innovations.

What are directed microperforations?

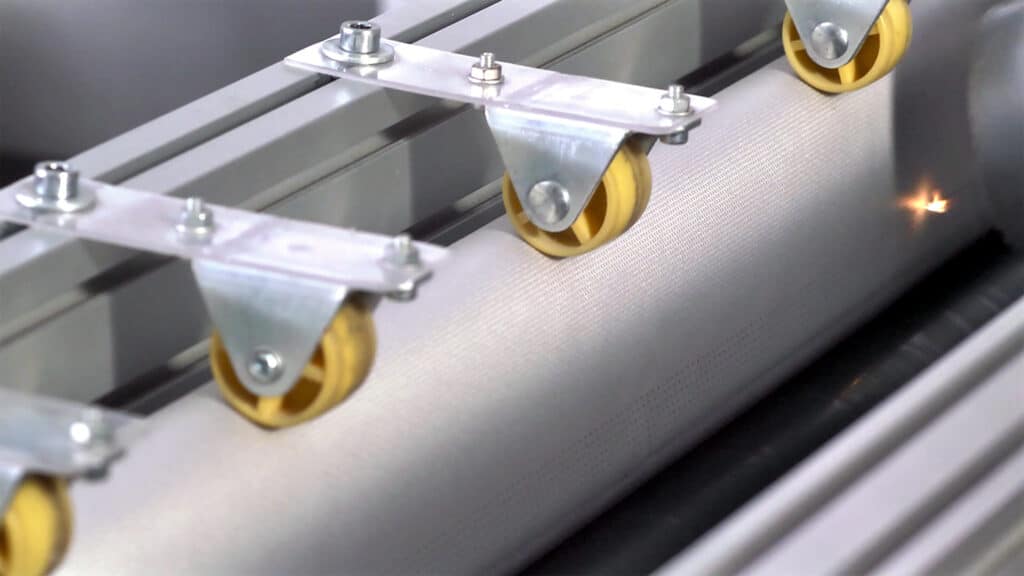

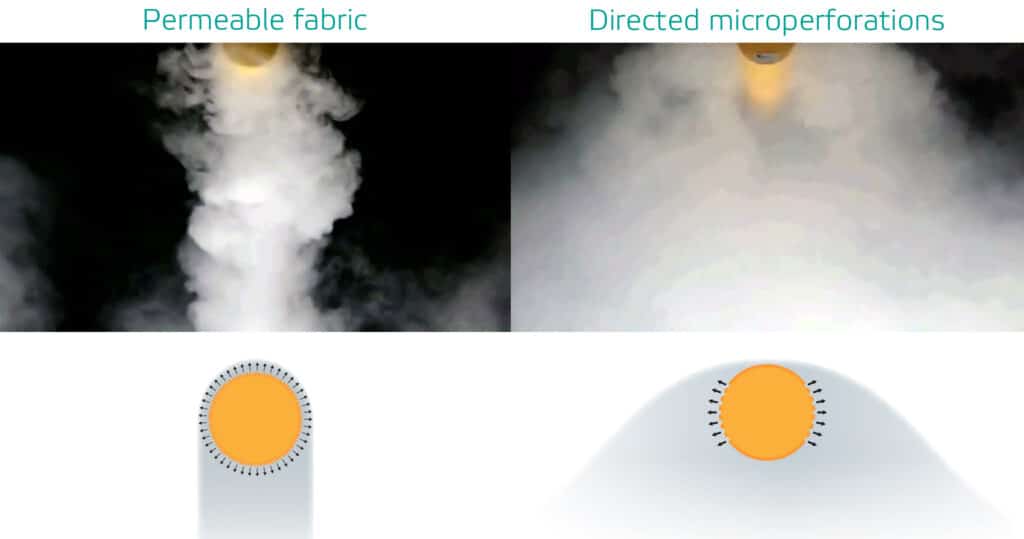

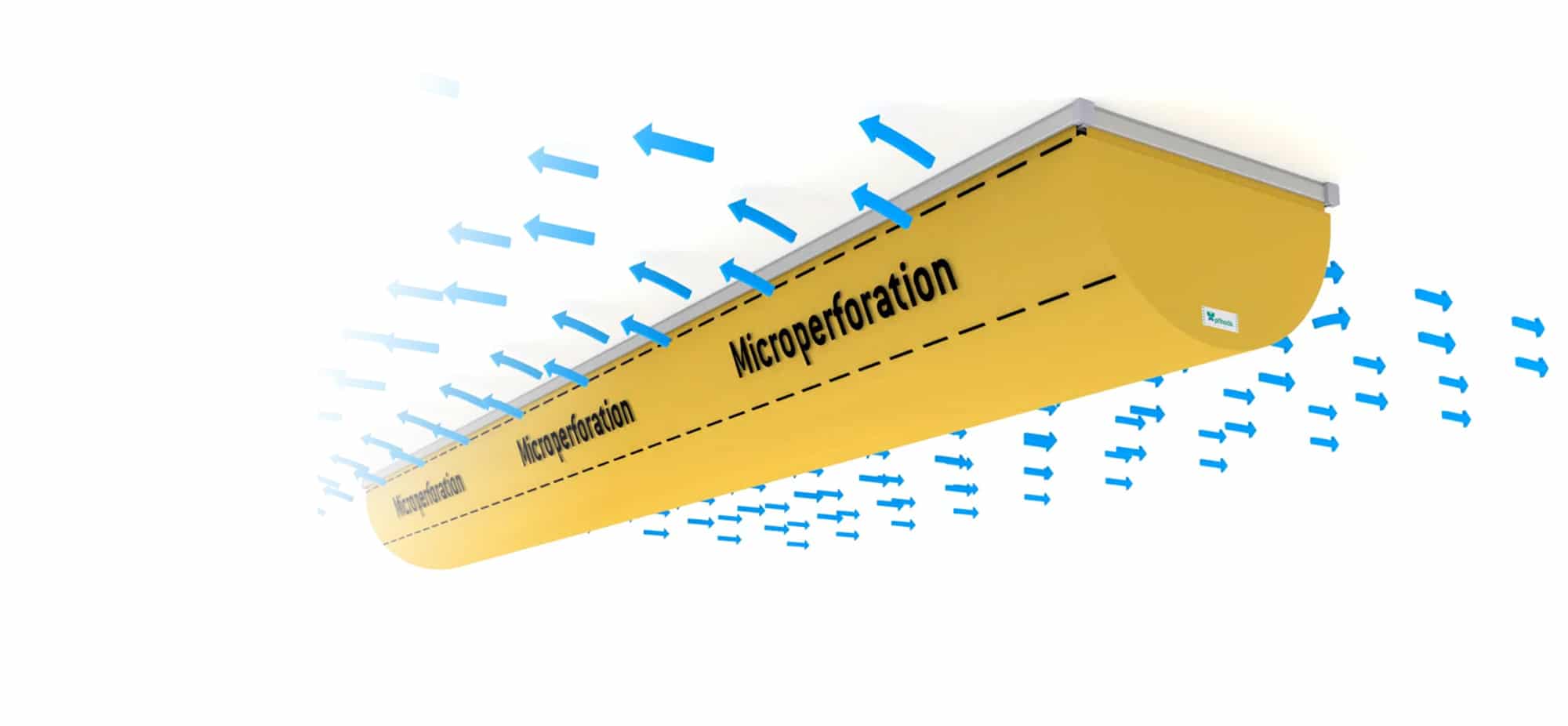

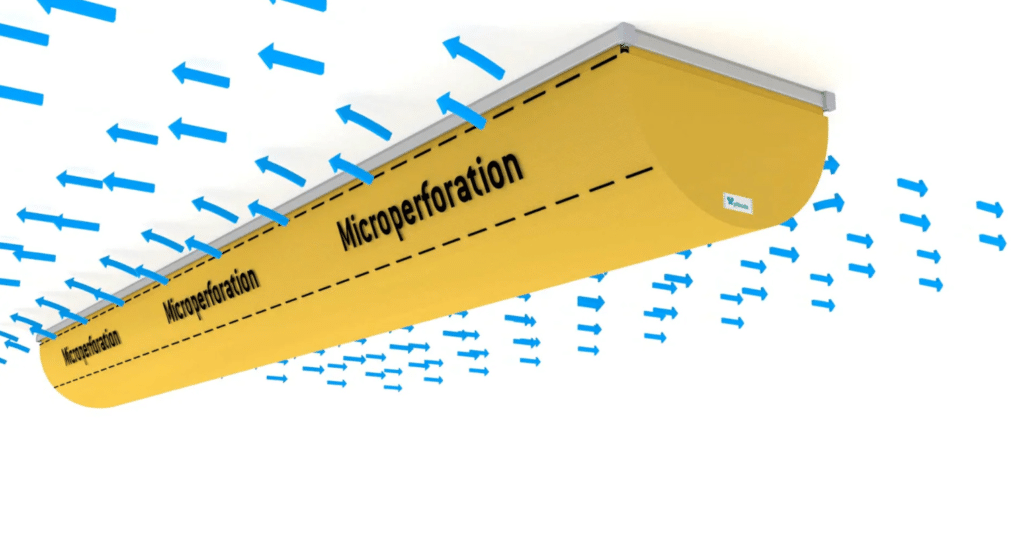

Directed microperforations are designed to deliver a gentle, draught-free stream of air aimed at specific directions. They are laser-cut precisely to a 0.2 to 0.4mm diameter, depending on design requirements, which results in softly diffused airflow. We can place them along specific sectors of the duct’s circumference, which allows exceptional flexibility and dramatically increases the use cases of microperforations.

Where are they used?

Directed microperforations are perfect where very low-velocity airflow is needed, such as labs, cleanrooms, and areas with low ceilings. They are particularly useful in cooling applications. Cooler air is denser and tends to sink. By placing microperforations in carefully calculated locations, we can avoid creating an unpleasant cold air column under the duct. This way, an extremely gentle, diffused, whisper-quiet flow can be achieved, even when diffusing very large volumes of air. For example, a typical laboratory needs at least six air changes per hour to keep the air clean and safe for occupants. However, draughts, noise and temperature fluctuations can cause issues with lab equipment such as fume cupboards. By setting microperforations to diffuse the air at certain angles, we can easily fulfil the air volume requirement without interfering with sensors and equipment.

More design flexibility

All our diffusers are compatible with microperforations. For more directed or longer-throw supply air, we can combine microperforations with standard laser-cut perforations. Using our AirTailor software, we can predict the interaction of the air flowing through each type of diffuser. This way, we can select the optimal diffuser parameters for each design. Combining diffusers adds another layer of customization, enabling precise results that closely follow specification. That’s how we can design a bespoke system that is perfect for your needs.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us