Fabric Duct Calculator: When To Use It And Why

You may have noticed the fabric duct calculator on this site or even downloaded the mobile app. You might be wondering, why use the calculator if you can talk to us directly? We have developed our easy-to-use fabric duct calculator for times when you want a quick check of which duct shape and size might work in your project. Unlike rigid ducting, fabric ducting must be inflated by the pressure of the air flowing through it. This makes the correct sizing of the ducts a crucial part of the design process. In this post we will give an overview of how and why you might consider using our fabric duct calculator when considering Prihoda fabric ducts.

When and how to use the calculator?

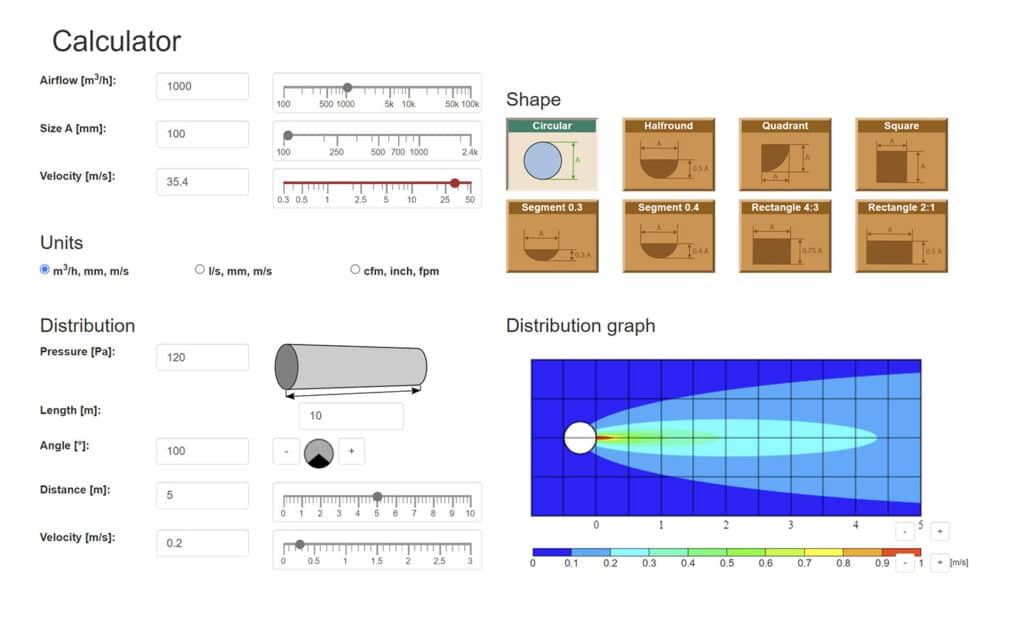

Using the calculator couldn’t be easier. Simply select the required duct shape and your preferred units. Then input the airflow volume and pressure (if known), and adjust the size to see the effect on the distribution graph.

You might consider using the calculator if: you’re sizing a single duct, you want to explore how the duct shape can change the resulting air distribution, or you want to check the effect you can expect if you change one of the basic parameters, such as the air volume.

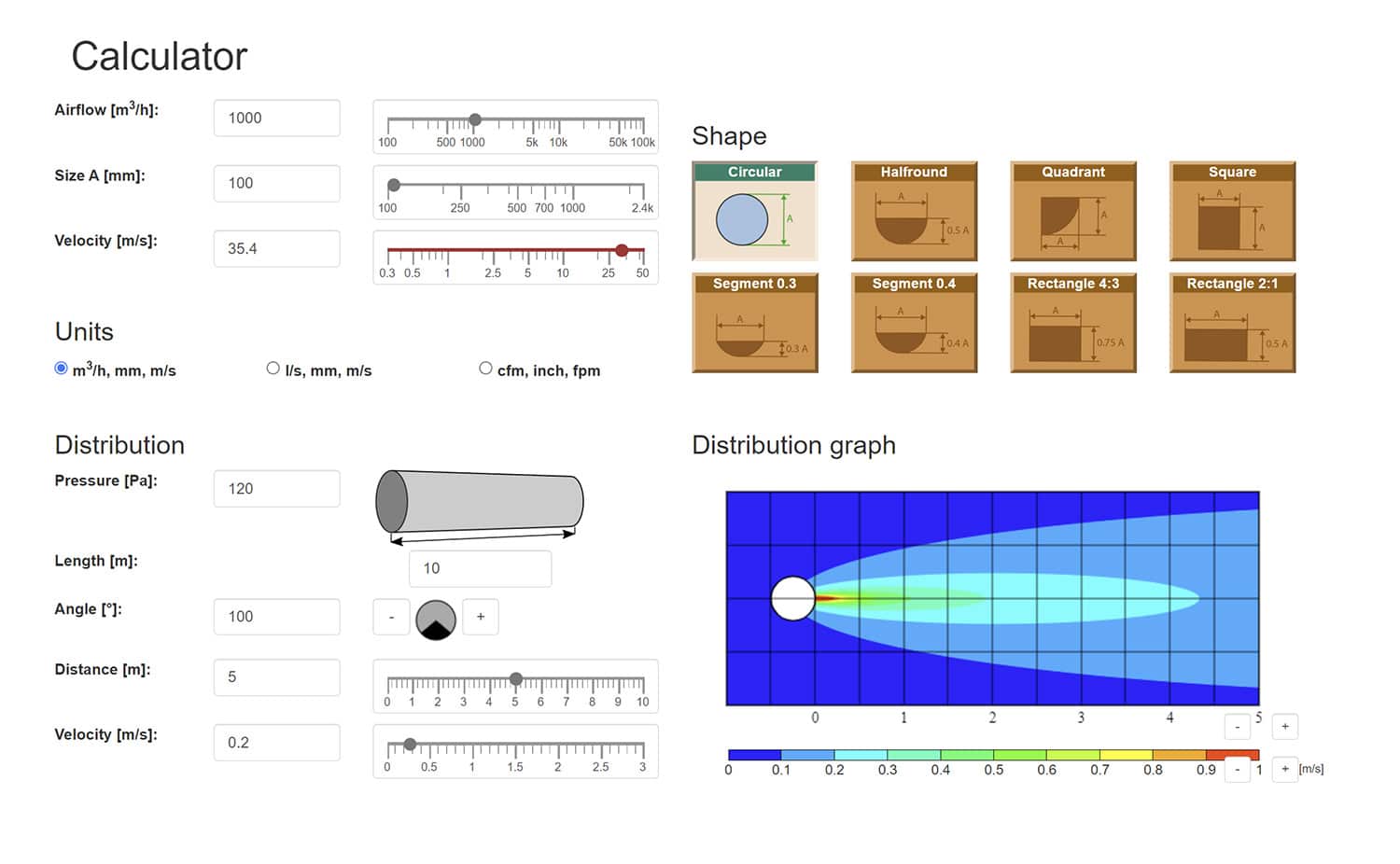

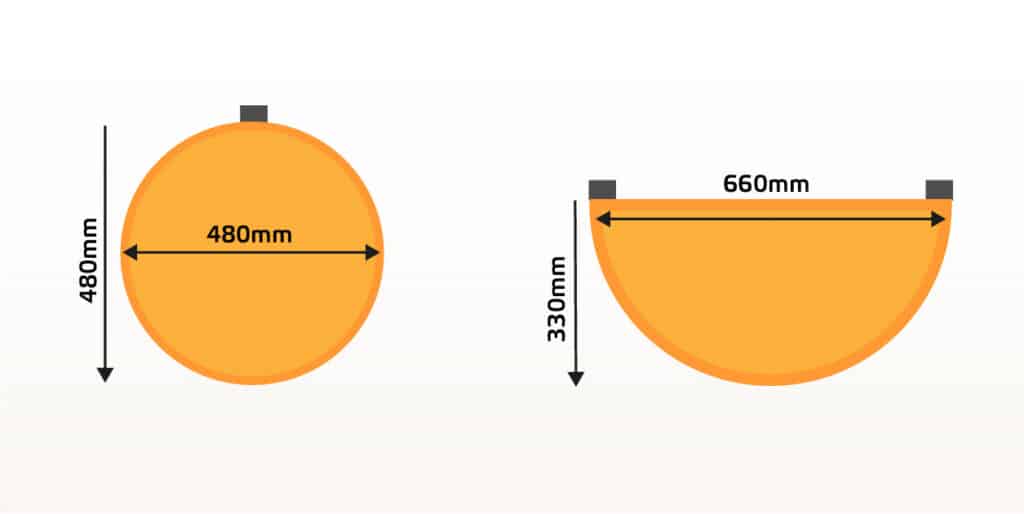

For example, suppose you are deciding between a round or a D-shaped fabric duct. You can use the calculator to get an idea of how the shape will affect the required size for your available air volume. If your air volume is 3,000m³/h and your application requires maximum 5m/s in-duct velocity, you will need a Ø480mm round duct. But what if you select a D-shape duct? If you click on the D-shape option and adjust the velocity back to 5m/s, the required size is now Ø660mm. If the duct will be installed in an area with lots of other services, choosing the D-shaped option might make the duct too wide to fit in the available space. Or it might be the better option if the ceiling is very low, as its profile will only be 330mm deep, vs 480mm for the round duct.

We usually recommend making the selection based on an in-duct air velocity of 5m/s. Why 5m/s? We find that this rough limit gives a good balance between performance and noise levels for most general applications. A higher velocity can result in problems with excessive noise or duct movement.

Of course, this velocity limit won’t always suit the application. You might consider a lower velocity for very quiet applications, such as theatres or cinemas, or a higher velocity for heavier industry with substantial air volumes and where noise isn’t a main concern.

Some considerations…

The calculator is designed to quickly try out the different options before getting deeper into the duct design, so it comes with some limitations. It disregards the temperature difference Δt between the supply air and the surroundings. As the relative density of the air is a function of Δt, without knowing Δt we can’t give a precise prediction of the expected air pattern. Even with isothermal air, the air distribution also depends on the diffuser type.

Microperforations give very short throw, whereas the air from large nozzles can travel up to 30 metres! The calculator disregards the diffusers – diffuser selection can be a complex matter. If you’d like to know more about diffuser types and how to position them on the duct, click here for the CPD course.

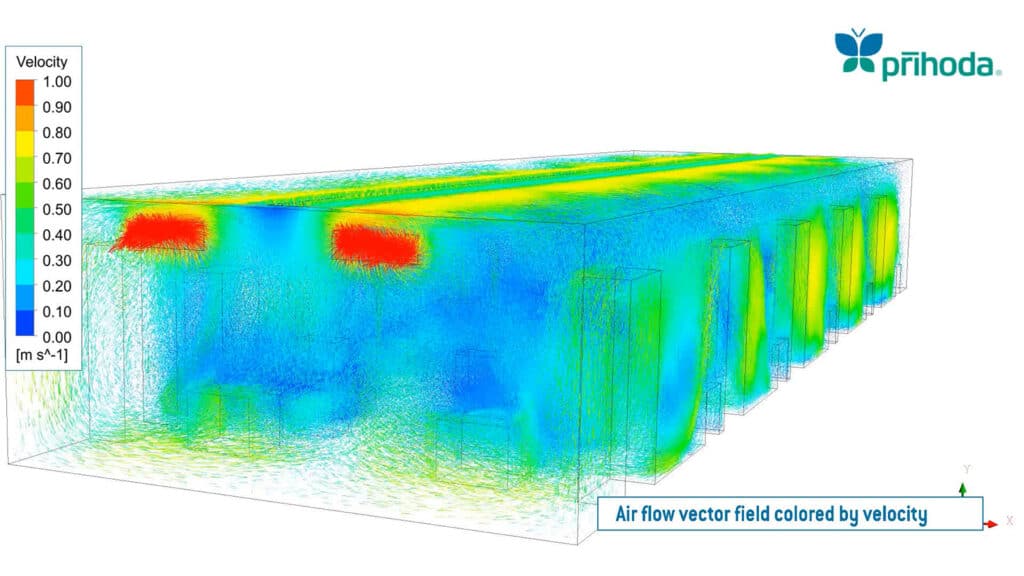

The calculator also can’t show the interaction between the air distribution coming from multiple ducts into the same room. For example, for a system consisting of a header duct with several branches, the air from each branch will interact and mix with the air from all the other branches.

We’re here to help

Contact us to discuss the airflow requirements of your project. We can provide a comprehensive technical report including duct sizing and layouts, diffuser options and expected air patterns. For more detailed distribution patterns, such as for very critical projects, we can also provide CFD simulations. Please contact us for pricing.

Why Prihoda?

We have over two decades of experience designing and manufacturing fabric ducting for every application. Factories, data centres, hospitals… if you can name it, we have worked with it. We want to ensure that your fabric ducts are exactly what your project needs. That’s why we provide support from the earliest stages of design all the way to after-sales services. With a 10-year warranty on our most popular materials and our in-house professional laundry service, Prihoda fabric ducts are the ideal alternative to traditional rigid ducting. No draughts, no noise.

Contact us for an informal chat about your requirements.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us