Fabric Ducts: Your First Choice For Fire Safe Ducting

Accidents and fires are an unfortunate part of life. We can’t avoid them all the time; all we can do is mitigate the risk. In recent years, there’s been a trend towards taking a regulatory approach to fire safety, and for good reason too. According to official statistics from fire and rescue services, every year an average of 294 people die in England as a result of a building fire, including private dwellings and other buildings such as offices. In total, there are almost 63,000 yearly fires. It’s evident, then, that minimising fire risk is crucial to the safety of the building’s occupants.

To this end, the construction industry has introduced fire safety guidelines, rules and regulations designed to minimise risk for everyone, including workers and end users, from design through site work to finished units. These rules and guidelines focus on a wide range of topics: means of escape, fire extinguishing, ignition sources, etc. For engineers and specifiers, all aspects are important, as all work must comply with regulations. But from the perspective of a building’s occupiers, ignition sources and combustible materials are an especially significant concern. After all, without combustible materials and ignition sources, there would be no fires.

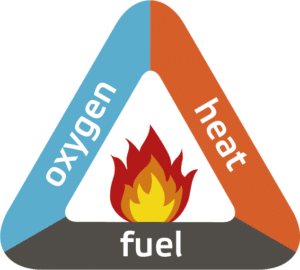

Ventilation products must also comply with fire safety guidelines. In the UK, the regulatory environment surrounding fire safety is currently somewhat in flux. In light of recent high-profile tragedies, the rules are in the process of being reviewed and updated. However, the core principles remain the same regardless of any law changes. All fires start and are kept going by the same three factors (known as the “fire triangle”): heat, fuel and oxygen. Removing one of these factors will end the fire or prevent it from starting in the first place.

How can fabric ducting help?

Prihoda fabric ducting is designed with safety in mind:

Material – It may sound strange to think of fabric as a fire-safe material, but our unique fabric material was developed to be fire resistant and flame retardant. It is self-extinguishing, so in the event of a fire, it won’t support the flames. It also doesn’t cause flaming droplets or produce smoke, facilitating the means of escape for the occupants of the building.

Diffusers – All our diffuser options are made of the same material as the rest of the duct, which gives them the same material properties and, therefore, the same fire safety characteristics. Even our nozzles, which come in many sizes and configurations, are made of the same fabric material. There are several reasons for this design choice, but one of them is fire safety. Unlike plastic nozzles, which usually support a flame and can melt dangerously onto escaping building occupants, our fabric nozzles are flame retardant, virtually smokeless in a fire, and don’t melt.

Fire certification – For peace of mind, our products are tested and certified for fire safety. We have achieved a fire rating of B-s1, d0 in compliance with EN 13501-1+A1:2010.

Accidental fires aren’t always preventable, but we can all do our part to minimise fire risk. For engineers and specifiers, this means ensuring that all processes and materials are designed with fire safety in mind. Fabric ducting is an excellent choice due to its flame-retardant material. But that’s not all it can offer: our classic material comes with a 10-year warranty, and all our fabric duct systems are designed bespoke to provide the ideal airflow patterns for your project, supplying the right amount of air exactly where it is needed.

From design to maintenance, Prihoda offers a comprehensive range of fabric ducting services.

Please contact us to find out more.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us