How Do Fabric Ducts Maintain Their Shape?

Unlike traditional rigid ducting, fabric ducting is made of pliable textile material that needs to be inflated into the right shape during its operation. There are several ways to achieve this and many different factors that might affect which approach we choose for a particular project. In this article we will explore the different options we can use to ensure that your fabric ducts maintain the correct shape for flawless performance throughout their operating life.

How do fabric ducts remain inflated, and why is the correct duct shape important?

To answer this question, we must first understand the air pressure and how it changes inside a ventilation duct. As air flows through the duct, it exerts an outward pressure on its walls. This is the static pressure – the potential energy of a unit of air at a particular cross-section. In a very long straight duct, there can be significant losses due to the friction. Progressively decreasing the duct diameter along the length can help prevent issues. The air also suffers other losses as it flows, for example, whenever it changes direction in bends and arches. The longer the duct, the rougher its surfaces, and the more geometric complexity, the bigger the pressure losses of the air in the duct. With fabric ducting, we must take all these things into account to ensure that the duct remains inflated, maintains its cross-section and therefore operates as designed.

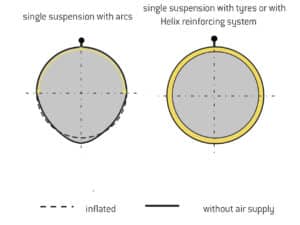

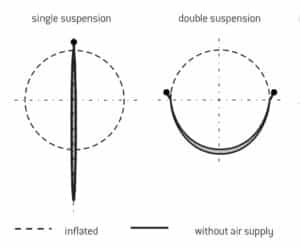

It’s not always feasible to supply a constant air volume. When the airflow is reduced or switched off, fabric ducts will typically deflate and hang in place. This is not always a problem in applications where the aesthetic qualities of the ductwork aren’t a priority, e.g., in warehouses and some industrial settings. But it can give rise to problems in certain applications, either because it interferes with nearby equipment or because their appearance is important, such as in retail, hospitals or gyms. The shape of the uninflated duct depends on the way it was installed. In a cleanroom environment where the fabric ductwork is typically half-round and attached directly to the ceiling, the deflated shape will be similar to when it’s inflated, whereas a round duct with single rail suspension presents a drastically different duct shape when fully deflated.

What happens if the duct deflates?

A fully deflated fabric duct isn’t necessarily an issue, but in some cases it can be. Once deflated, a round duct with single suspension is approximately 1.3 times longer than the diameter of the inflated duct. This extra space needs to be considered at design stage to prevent any issues with lighting, other services, and the equipment below.

Unless the airflow is completely turned off, the duct will generally only deflate partially, which can cause unwanted movement and noise as well as being less aesthetic. Additionally, the variable cross-sectional area can negatively affect the performance of the fabric duct system. For situations where deflation is a concern, there are several ways to ensure that the correct cross-section will be maintained regardless of airflow levels.

How to maintain the right shape in variable flow conditions?

We can add some structure to the duct so that it will keep its original cross-section. Here are some of the options we have available:

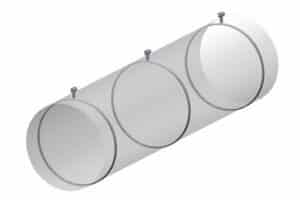

Tyres

Prihoda’s duct tyres (or rings) were developed to give fabric ducts a more rigid structure while preserving their lightness and versatility. There are two versions: internal and external tyres. As with all Prihoda products, they are made to perfectly fit your bespoke fabric ducts. We typically select internal aluminium rings set to 1,000mm spacing by standard. This offers the advantages of being lightweight, invisible and resistant to deformation in heating applications. Internal rings are held in place by means of special Velcro tabs sewn to the inside of the duct.

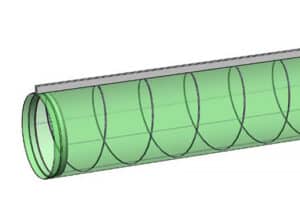

Helix

Our helix option follows a similar concept as the internal tyres, but instead of being made up of discrete rings, the helical structure is formed as one continuous spiral that is inserted through a textile channel inside each 5-metre section of the fabric duct.

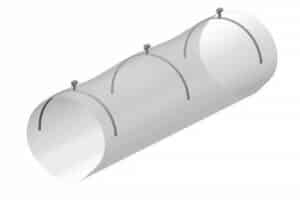

Arcs

These are shaped hangers which are inserted into sewn pockets and attached with Velcro. They work slightly differently to the options listed above. Instead of holding a round duct open all along the perimeter, arc hangers only hold the top of the duct with enough shape to help the bottom section hang correctly. They are a more economical option suitable for cases where only a little extra support is needed.

We include the option for internal rings by standard with every round fabric duct quotation. Let us know if your application has any additional requirements in terms of aesthetics or airflow.

Over the years, Prihoda has developed several innovations to ensure that your fabric ducting always operates as intended. Available in 9 stock colours at no extra charge and a 10-year warranty on our most popular materials.

Contact us for more information.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us