Hygienic ventilation for the food industry

When designing a food processing factory, one must consider every component: from the layout of the plant to the surface finish of the equipment within. The stakes are very high. Food contamination is a cause of foodborne illness, but also spoilage. Worldwide, the loss of food stock through microbial contamination and spoilage costs businesses millions of dollars every year.

The level of risk depends on the food being processed. For example, highly acidic condiments are rarely at risk of spoilage during their processing. On the other hand, ready-to-eat foodstuffs like salads and sandwiches are extremely sensitive to spoilage and must be processed in a high care environment under positive pressure.

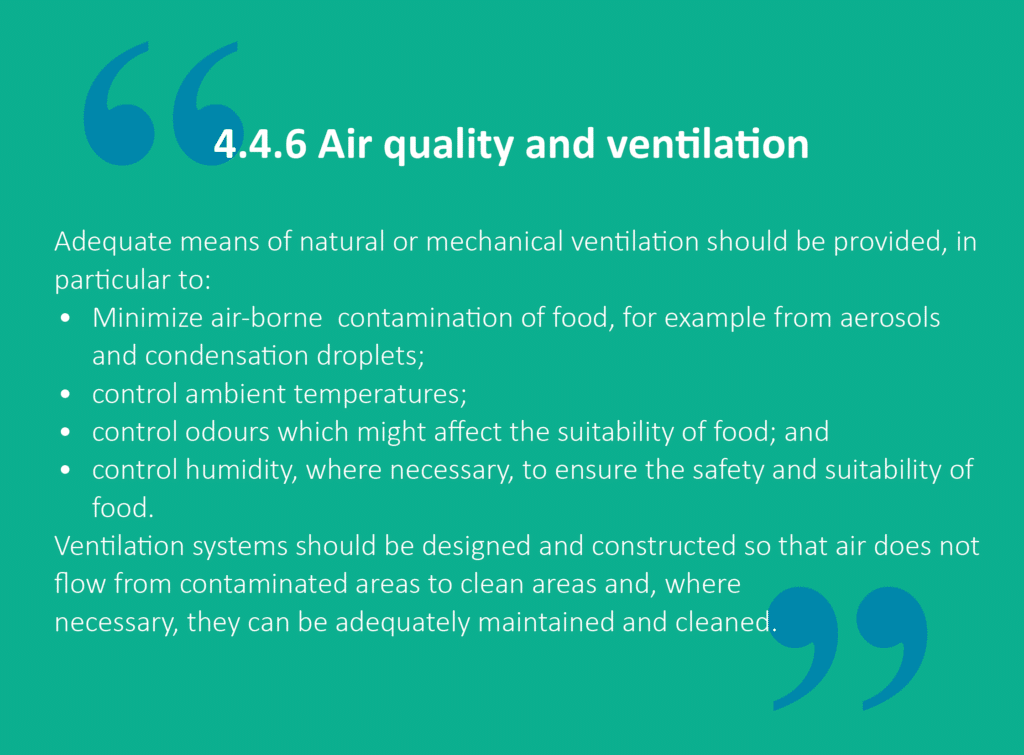

We have seen the impact of food contamination, but what does it have to do with ventilation ducting? Air quality is a vital aspect of the hygiene requirements of the food industry. The Codex Alimentarius sets out these guidelines for the ventilation of food establishments:

Yet the engineering focus is often on the air handling and filtering, neglecting to some degree the air delivery system, that is, the ducts and diffusers. It’s essential to choose air ducting that is resistant to bacterial proliferation, isn’t prone to soiling, and is easy to clean and sanitise periodically as part of the hygiene protocols of the food factory. And these protocols can be very stringent, particularly in high care zones, where food contamination is an ever-present risk that can arrive from anywhere, inside or outside the plant.

Airborne contamination

Ventilation is an integral part of the food industry’s defence mechanisms against food contamination. The clean delivery of conditioned air is just as important as the initial filtering.

Consider, for example, a factory which handles wheat or soy flour. These are allergens that tend to float in the air, accumulating on every rough surface, every nook and cranny. Low-velocity food industry ventilation prevents the uncontrolled spread of these ingredients, making it crucial in allergen management programs.

Likewise, low-velocity air distribution goes a long way towards minimising the spread of airborne sources of contamination, including aerosols and droplets from food processing. Combined with correct zoning, this is an extremely effective way to mitigate the risk of airborne pathogens and microbial contamination. The easiest way to achieve it is a with fine-tuned air distribution system like fabric ducting, especially with the large air volumes typically required in food facilities. It is also achievable with carefully designed steel rigid ducts, but this option is both more expensive and much more difficult to get just right.

Cleanable surfaces

Some foods are prone to dispersing through air currents and settling everywhere. Over time, these can accumulate in hard to reach areas and on top of metal ductwork. The European Hygienic Engineering and Design Group, which publishes guidelines for the hygienic design of food manufacturing facilities, specifies that surfaces must be easy to clean and non-absorbent, and “must be smooth and free of imperfections (e.g. crevices and cracks) to prevent harbouring of microorganisms and other residues.” Even with the most advanced ventilation, cleaning of all surfaces must take place regularly. Otherwise, food and detritus will accumulate and harbour microorganisms which can become a source of contamination.

For stainless steel ductwork, this means polishing every surface and weld to an Ra-value of less than 0.8µm. Fabric ducting is the obvious option in this case: no accumulation points, non-absorbent material, and it can be cleaned very thoroughly by washing in a washing machine. The material can even be treated to make it anti-bacterial.

Temperature and condensation

Temperature and condensation

Adequate ventilation is especially critical in temperature-sensitive operations such as ready-to-eat food production and slaughterhouses. Cooling must be present not just to reduce ambient temperature, but also to counter the heat generated by process equipment, which means the supply of large amounts of cold air at very low velocities. This is where fabric ducting really shines. Since the entire surface of the ducts can diffuse the air, supplying high air volumes without unwanted draughts and currents becomes a trivial matter. With a bespoke design and airflow mapping, dead zones and hot spots can be easily eliminated – making temperature control a breeze.

Lower temperatures lead to another concern: condensation. With colder supply temperatures there is a greater risk of condensation forming around ventilation ductwork, especially if it’s made of metal. Some foods, such as powdered baby formula, are particularly sensitive to spoilage from condensation. If the powder mixes with moisture from condensed droplets, it becomes the ideal breeding ground for potentially pathogenic microorganisms. Preventing ‘ductwork sweating’ is of paramount importance in food processing plants. Thankfully, avoiding this problem is very straightforward – simply use textile ducts made with permeable material. That way no condensation can form on the surface of the ductwork. Problem solved.

Conclusion

Selecting the right ventilation solution for food processing facilities is vital to the safety of food products. Airborne contaminants, air currents, temperature fluctuations and condensation are all risk factors that must be considered to make the right choice.

At Prihoda, we can make the task easier. With many years of experience with fabric ducting for food factories, we understand what is at stake. We offer bespoke, engineered fabric ducting from design to installation.

Want to know more? Get in touch

"*" indicates required fields

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us