Amazon Rugby Fulfilment Centre

The Company

From its humble beginnings as an independent online bookstore, Amazon has grown to become the world’s largest online marketplace. Its e-commerce platform sells everything from gadgets to groceries. Amazon owes its popularity with consumers to its incredible delivery efficiency. Using a distribution network of over 175 highly automated fulfilment centres, they can pick, pack and ship millions of items every day, often on same-day or next-day delivery schedules.

The Challenge

Recent years have witnessed a rapid expansion of Amazon’s operations in the UK. As part of its growth, Amazon has opened a beer, wine and spirits fulfilment centre in Rugby, West Midlands. With an area of over 270,000 sq ft and 5km of conveyor belts, designing adequate ventilation for employee comfort would be a big challenge. The enormous size of the fulfilment centre presented the usual difficulties of warehouse ventilation, but with a twist. Some areas were low-ceilinged mezzanine sections, which required a low-velocity air supply to avoid uncomfortable draughts. The air needed to be directed towards the occupied zones as all the automation equipment, racks and structural columns would interfere with the airflow. Furthermore, the exposed utilities, cabling and other building services represented an obstacle to ventilation ductwork.

Our Work

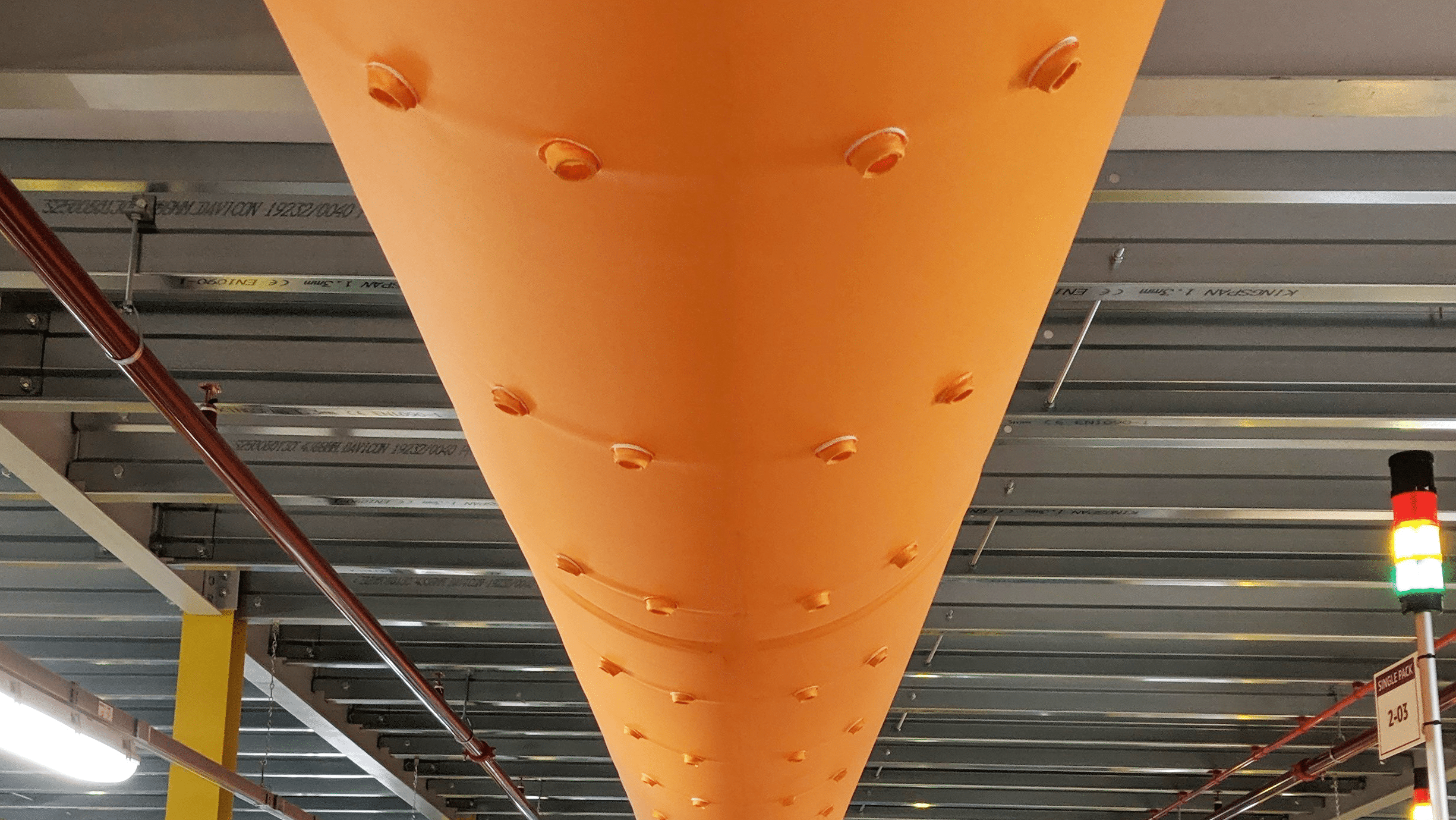

We designed and supplied thousands of metres of round fabric ducts as part of several systems. Every system was specially engineered to address the warehouse ventilation needs of each area for maximum employee comfort. Directed supply was achieved using four rows of small, low-velocity nozzles. In the mezzanine areas, gentle 45° duct bends were introduced where necessary to leave room for the other utilities suspended from the low ceilings.

Fire resistance was an essential consideration in this project due to the alcohol content of the products stored and delivered from this fulfilment centre. The textile material used to manufacture Prihoda ducts is certified to European standard EN 13501-1, class B-s1, d0. It is self-extinguishing and does not form flaming droplets.

The Outcome

This was a truly bespoke design. Amazon chose a special shade of orange to match their corporate branding and give a unified look to this warehouse.

The result is a well-ventilated warehouse environment, ensuring the comfort and safety of the employees of this Amazon fulfilment centre. Airflow is not blocked by equipment and product racks but directed to the occupied zones quietly and without creating an unpleasant draught.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us