How To Select Fabric Duct Material

One of the many advantages of fabric ducting is that it is always made especially for each particular application. Every aspect of a design is carefully chosen to address the requirements of the project. Material selection is no exception. But with a wide range of materials available, how can we ensure that we’re making the right choice? The selection process requires careful thought, but it is largely dependent on the type of application and the HVAC requirements of the project.

How does the application affect fabric duct material selection?

The environment in which we will install the fabric ducts is a central consideration when selecting the material for a fabric duct design. Will they be installed in a shop? A factory? Knowing the context helps us understand the design’s main priorities and what characteristics are essential to the application. For example, sanitary conditions are the top priority in a hospital environment to support disease control efforts. This requirement makes easy-to-clean antibacterial material the most appropriate choice. By contrast, in retail applications, hygiene is a less pressing matter. There is generally a desire to build brand awareness where possible, making printed material with logos or brand colours more useful in this case. In a short-term application or for a project set in a very lightweight structure, such as a marquee or a tent, the material selection would favour our Lightweight Classic material.

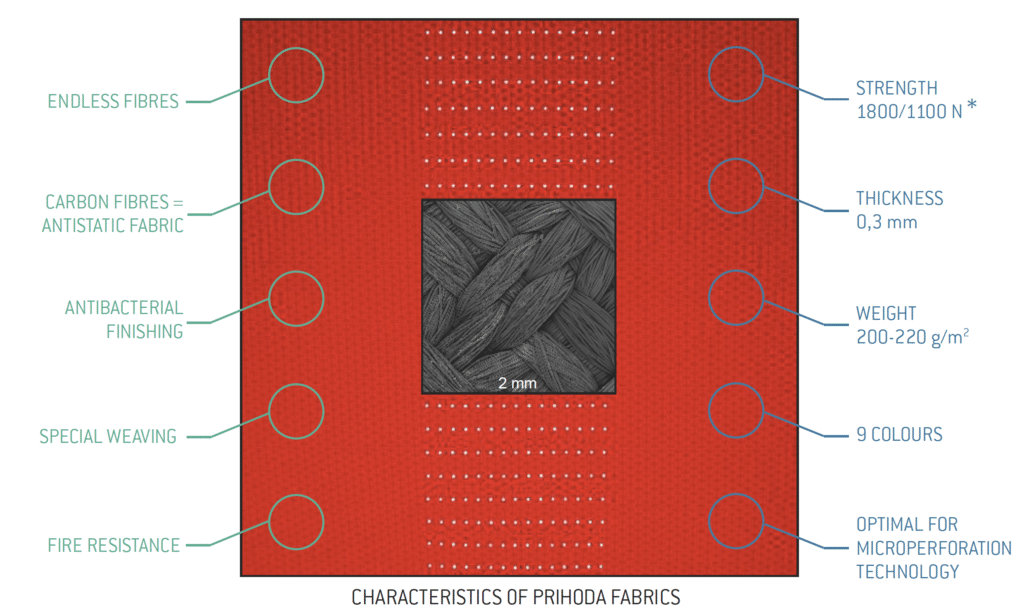

Regardless of the application, fire safety and effortless cleaning are always covered, as our most popular fabric duct materials are fire-resistant and machine washable. They are also suitable for cleanrooms thanks to their multifilament structure, made up of endless fibres which do not become loose and shed as can happen with staple fibre materials.

Permeable or impermeable material?

The heating, cooling and ventilation requirements also help determine the best textile duct material for a ventilation project. We would typically select an impermeable material so that we can control all the air dispersion using diffuser outlets such as microperforations and nozzles. However, we use permeable material in cooling applications where the supply air temperature will be lower than the dew point, such as in food manufacturing. By using permeable material, we prevent water condensation from forming and depositing on the duct’s surface. Alternatively, for transport ducting applications without air dispersion, we can also use insulated double-walled textile ducting.

Typical examples

Classic material: our most popular material for industrial and commercial ventilation systems. It is a medium weight multifilament material, suitable for most applications that don’t need specialist features such as antistatic or antibacterial treatments. For example, fabric duct system designs for shops, warehouses and restaurants are often made with Classic material.

Recycled material: physically identical to our Classic material but made of Repreve fabric, whose fibres have been manufactured from post-consumer recycled plastic bottles. As with the Classic material, our recycled material is suitable for most applications, especially for BREEAM or LEED-certified projects.

Premium material: similar to Classic but with antistatic and antibacterial protection. It contains inwrought carbon fibres to prevent static build-up in the ducts. The antibacterial properties are achieved using antimicrobial Dupont Silvadur technology, which kills microorganisms on contact with the fabric’s surface. The antibacterial quality of this material makes it perfect for hospital and food manufacturing applications. Electronics manufacturing facilities and industries involving fine particles (e.g., flour) can also benefit from the Premium material’s antistatic treatment.

Lightweight Classic material: at 70 g/m2, this is our most lightweight material available. It is designed especially for applications such as marquees and other temporary installations with lightweight roof structures.

To discuss the requirements of your project, please contact us using the form below.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us