Membrane Diffusers: What They Are And Where To Use Them

One of the significant benefits of using fabric ducting is that, unlike rigid ducting, it doesn’t require balancing. Every system is bespoke and is designed to deliver the exact airflow parameters specified for the application. This works very well in places with relatively stable conditions, such as in food manufacturing or meat processing facilities, where the temperature is always kept within a specific range. But what if you need to switch between intense heating and cooling in the same room at different times? We have developed our membrane diffuser to make such a system possible.

What is a membrane diffuser?

A membrane diffuser is a dual-mode fabric duct that operates as two separate diffusers combined into one. It can supply both hot and cold air when needed, even with vastly different temperature differences. And as with all Prihoda ducts, the air distribution pattern is optimised for each case, just like with a standard fabric duct.

How does it work?

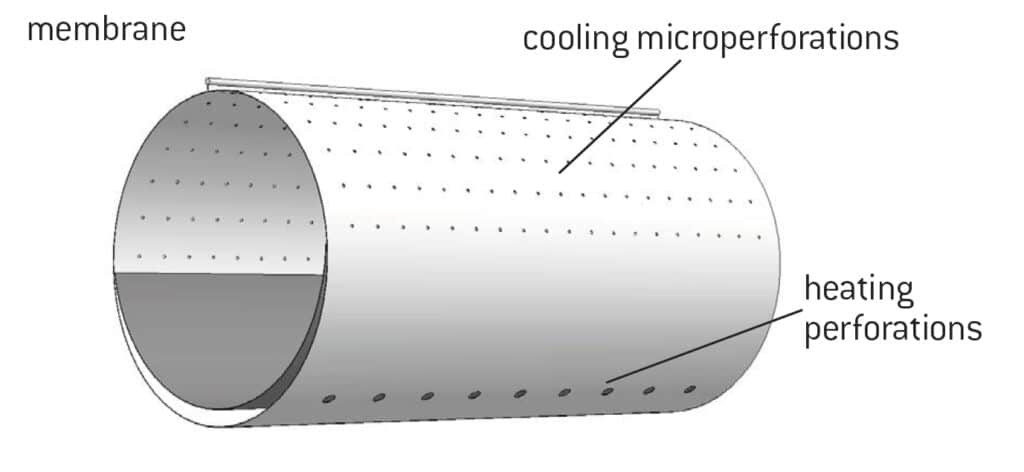

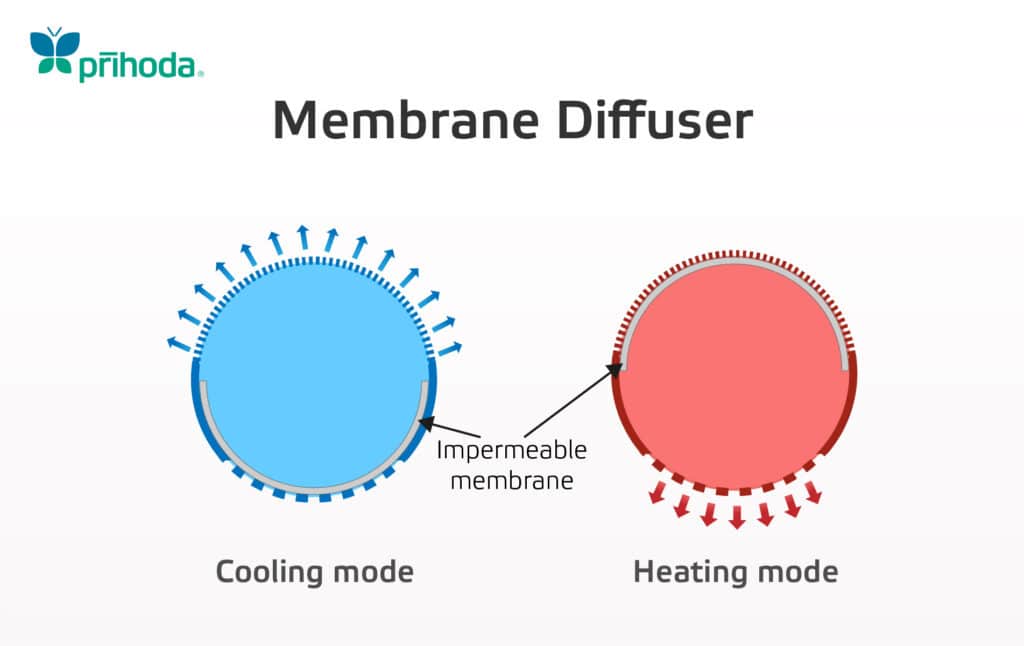

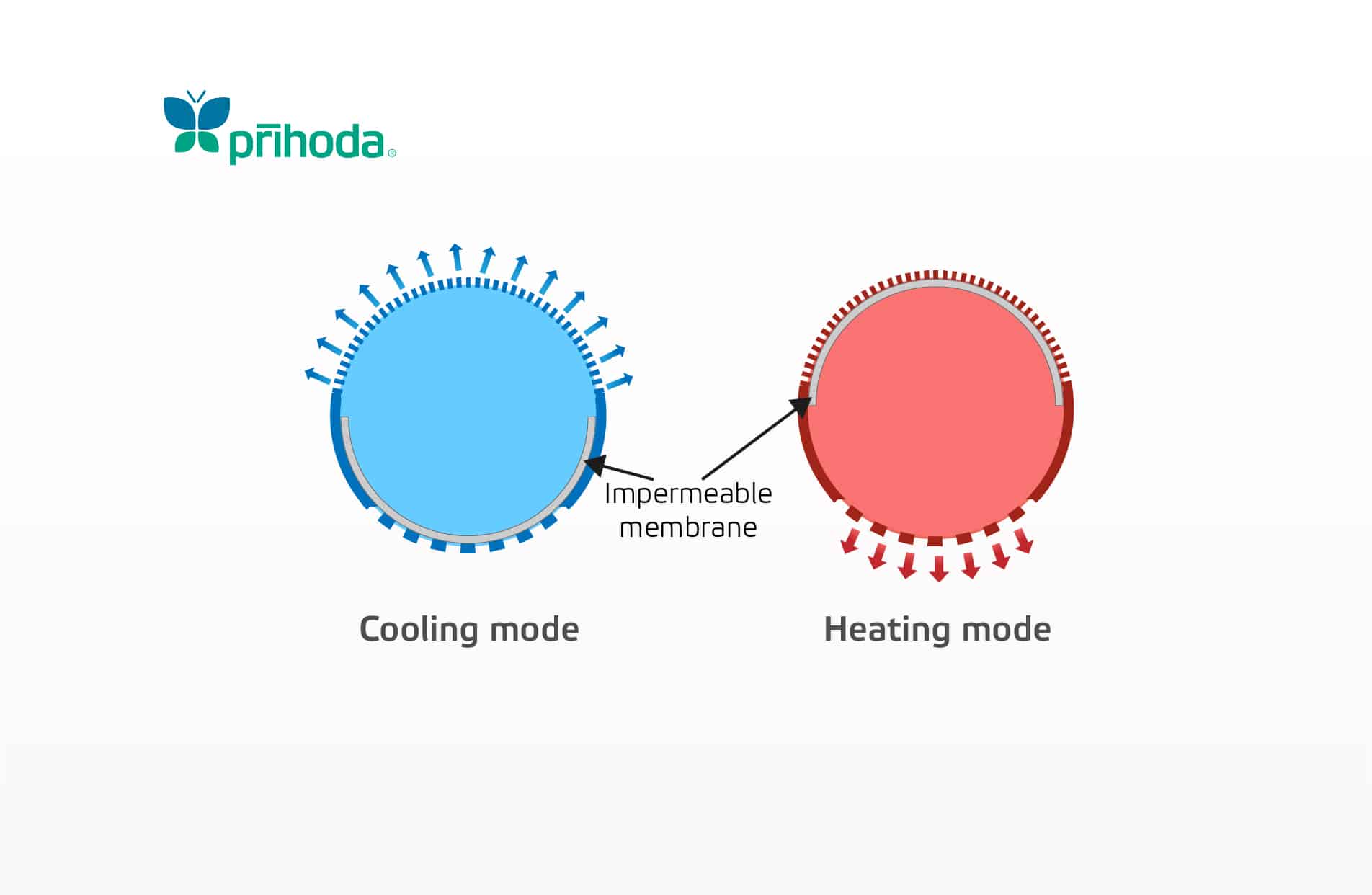

A membrane diffuser consists of a single fabric duct with perforations on the top and bottom surfaces. Inside the duct, a membrane made of non-permeable textile material covers one half of the internal surface.

In heating mode…

a servomotor on one end pushes the membrane to the top of the duct, blocking the upper perforations and allowing the heated air to diffuse through the bottom perforations.

In cooling mode…

the servomotor pushes the membrane to the bottom, and the cold air supply is distributed through the upper perforations. Since the supplied air is at a lower temperature than the ambient air, it falls under its weight without causing any unwanted draughts.

Why use membrane diffusers?

The main benefits of using membrane diffusers are superior performance and space savings. If your application’s supply air can be very hot or very cold at different times, your options may be limited with other types of diffuser. With traditional rigid metal ducting, the grilles and diffusers can’t adjust to accommodate different air densities, resulting in draughts and uneven performance. Standard fabric diffusers may also be unsuitable, as they are always designed for specific supply parameters. A membrane diffuser is ideal when a single fabric diffuser can’t give an optimal air pattern for both use cases. It provides a flexible approach without compromising on performance, while benefitting from all the advantages of using fabric ducts.

Want to know more?

For more information or to discuss how Prihoda fabric ducting can help your next project, please contact us. Our specialist team can help you find the best solution for your commercial or industrial ventilation requirements.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us