Not All Recycled Plastics Are The Same

Recent interest in the environment has driven many consumers to choose eco-friendly products made of biodegradable or recycled materials. Products claiming to be recycled are more available than ever, from consumer products to construction materials. But not all recycled plastics are created equal – some are more sustainable than others.

Post-consumer vs post-industrial recycled plastic

A product’s claim of containing ‘recycled content’ means it is made with post-consumer, post-industrial or mixed recycled plastic, without specifying which. But how does each of these differ from one another?

Post-industrial (or pre-consumer) recycled plastic is the waste plastic remaining from manufacturing other products. Offcuts, trimmings, and other waste plastic left over from industrial production can be recycled and labelled ‘recycled content’. While this is an efficient use of material, the process usually begins with virgin material. By contrast, post-consumer recycled plastic has already been used in a product, which the consumer has then discarded once it has fulfilled its intended use. Instead of going to landfill, it is washed, processed and recycled into a new product, remaining recyclable for another use cycle in the future. The benefits are obvious. One is industrial waste which has never been used before, while the other is consumer waste that would otherwise be destined for the landfill.

At Prihoda, we only use fully traceable, 100% post-consumer plastic to manufacture our recycled material. For each 1 m2 of material, 13 PET bottles are diverted from their course to the landfill. They are processed and spun into polyester fibres which are then woven into fabric, ready to be turned into Prihoda ducts.

Truly sustainable

When choosing an eco-friendly product, its entire lifecycle matters – from material sourcing, through energy use, to end of life processing. People hoping to lessen their environmental impact sometimes overlook an important factor: is the company behind the product genuinely sustainable? There is no point in choosing a recycled product if it was manufactured using harmful practices.

We are committed to sustainability because the environment is a cause very dear to us. From installing energy-efficient LEDs to switching to 100% recycled paper, we are always looking for ways to reduce our environmental impact. That’s why our central office’s electricity supply is generated exclusively from clean, renewable energy sources. We use dedicated recycling bins throughout our office to segregate all waste and recycle as much as we can. Even our printer ink cartridges are recycled! And of course, we use Prihoda SquAireTex swirl diffusers to ensure the optimum use of the air supplied by our MVHR system.

But what about microplastics?

A major concern with the use of plastics, recycled or not, is that they can potentially release microplastics into the environment. These are small plastic fragments of less than 5mm in length, but they can be as tiny as 1 µm in size. They are a significant source of marine plastic pollution and are known to be ingested by marine life, accumulating in aquatic animals’ body tissues. The effect of microplastics from the food chain on human health is unknown. Microplastics can be generated from many products and processes, but a substantial portion comes from textiles, packaging, and waste disposal processes.

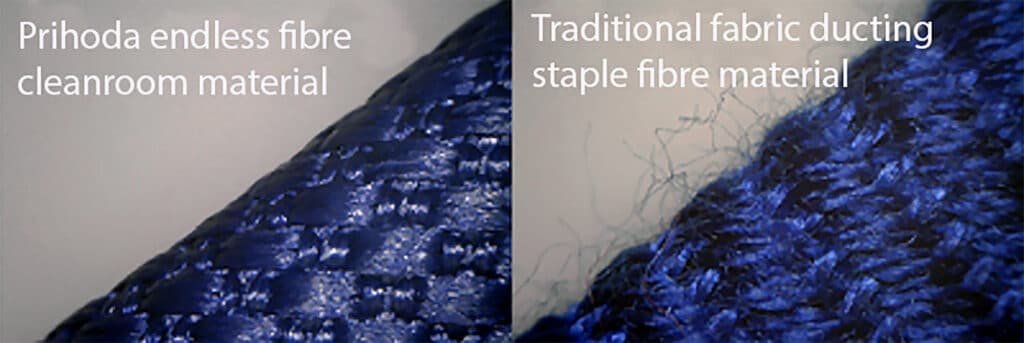

Prihoda fabric ducts and diffusers do not shed fibres into the environment, as they are made using endless multifilament fibres, rather than staple fibres which can fray and dislodge. We use manufacturing processes such as laser cutting and sonic welding to make our ducts, which don’t affect the material’s integrity. As a result, they are certified for use in cleanrooms to ISO 14644-1: Class 4 standard. And since they are made from recyclable materials, they can be recycled at the end of their usable life and turned into new ducts or other products. That way, the materials never have a chance to degrade and release microplastics into the environment.

Find out more

We can help reduce the environmental impact of your HVAC project. To find out more, or to get a free quote, please contact us using the form below.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us