Fabric Ducting Vs Rigid Ducting – When To Use Which?

At Prihoda, we are passionate about fabric ducting and are always interested in finding new ways to use it to solve your airflow challenges. But we consider fabric ducting a specialist product to be used alongside, and not instead of, other air duct and diffuser products. Each type of ducting, whether it is rigid or textile-based, has its place and its ideal use. So, what are the differences between fabric ducts and traditional metal rigid ducts, and where does each type work best? Read on to find out.

Bespoke vs off the shelf

The most important thing to remember about fabric ducting is that it is always bespoke. That means no stock product and therefore no ‘standard’ installation. This offers huge advantages in many applications, but it also brings its own set of challenges. In areas with tricky layouts or special requirements, designing and manufacturing a fabric duct system can be easier than an equivalent rigid duct system. Fabric ducts provide endless design flexibility: they are always designed from scratch for each project using textile material, which can be turned into ducts with different shapes and layouts, and with diffusers arranged in unlimited configurations. However, this same flexibility can often cause confusion among those who are less familiar with fabric ducting vs other types of ducting.

With rigid ducting such as galvanised ducts, parts are off the shelf and ready to go, but this convenience comes at the expense of how closely the design can adapt to the requirements of the project. For instance, if the application requires very large supply air volumes at a wide Δt, as is typical in food manufacturing, it’s easier to deliver the air through a large diffuser area. This is very easy to achieve with fabric ducting, whose entire surface can be used as a diffuser. With rigid ducting we usually rely on discrete grilles, which offer only a fraction of the diffusing area of a fabric diffuser.

The role of air pressure

Airflow pressure is always an important consideration in any HVAC system design, but there are differences in the specific role it plays in fabric vs metal ducting. As air flows through a duct, its pressure decreases due to friction with the inner walls. The pressure drop depends on the material and geometry of the duct – any bends, fittings, material roughness and so on cause more losses. All ductwork must be sized correctly to achieve a balance between having enough available pressure to transport the air efficiently, but not so much pressure that it causes excessive noise. Fabric ducts are no exception, but with one material quirk: fabric is pliable. As a result, most fabric ducts must be kept inflated by the static pressure of the air flowing through it, i.e., the force exerted by the air on the inner wall of the duct. This ensures that the full cross-section is used effectively. An oversized duct of any material is less efficient, but with fabric ducts, efficiency is built into the design.

Air distribution

Designing the air distribution with fabric ducting is very different from how it works with rigid ducting. This is because fabric ducts are generally dual purpose, distributing the air whilst also transporting it to where it is required. By contrast, rigid ducting in other materials nearly always serve only to carry the air from one place to another, and any distribution is achieved using diffusers such as louvres or grilles. As a result, positioning these diffusers correctly becomes critical to obtain the required level of airflow in the space. The location, density and spacing of diffuser features in fabric ducts are fully customisable to the application, while rigid ducts depend on separate diffuser equipment dotted around the space.

In conclusion, fabric ducting…

- is designed bespoke,

- depends on air pressure to remain inflated,

- diffuses air as it transports it,

- is made of a more cost-effective material.

Rigid ducting…

- is made up of off-the-shelf components,

- requires separate, discrete diffusers to deliver the air,

- is generally more expensive.

Application examples

If rigid and textile ducting are different and not fully interchangeable, where should each type be used? Here we will explore some of the applications that allow rigid and textile ducting to really shine.

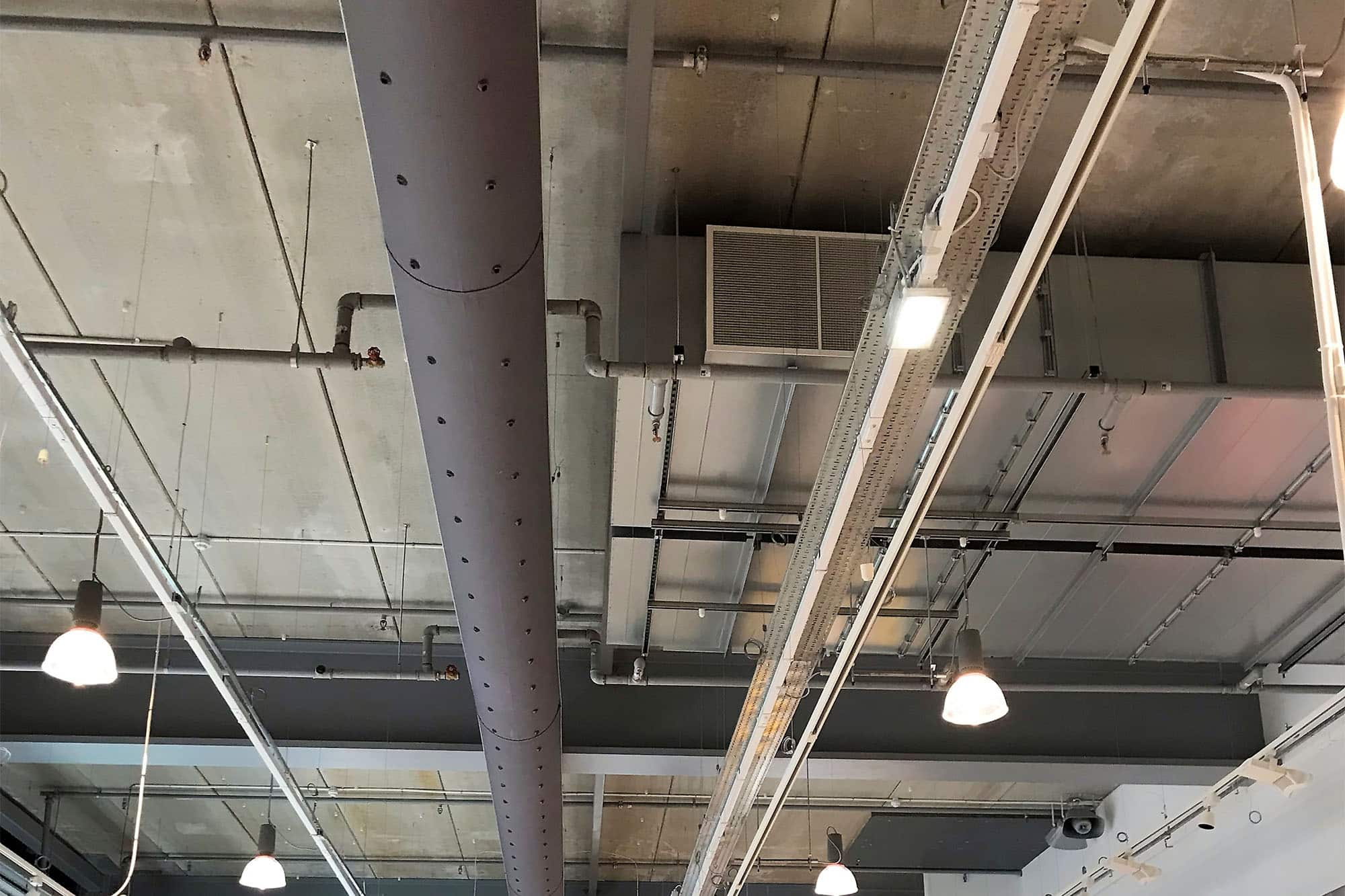

Rigid ducting works best where a lot of air needs to be carried from one part of a building to another; for example, from a roof-mounted air handling unit to a specific room. Once in the room, the supply air can be delivered and mixed into the existing air very efficiently using fabric diffusers with nozzles or perforations, depending on the airflow requirements. This way, the air distribution pattern can be designed precisely for the application, while taking advantage of easily available stock parts for the rest of the HVAC design.

Another typical approach is to set up the extract ducting in traditional rigid ducts with, e.g., bell mouths as the intake, and use fabric diffusers to supply the air into the room. While fabric ducting can and is sometimes used in negative pressure applications with a rigid external frame, the mixed approach described above is quite common and very practical. It benefits from the strengths of both textile and rigid ducting in a convenient and straightforward way.

Why Prihoda?

We have two decades of experience working with fabric ducts and diffusers in a wide range of applications, from agricultural, through universities and schools, to complex healthcare and cleanroom facilities.

Contact us if you would like to discuss your requirements.

Looking for more information?

Our experts are on hand to answer any questions. Why not give us a call or drop us a message, We’ll work with you to find the right solution.

Contact us